North finders have entered everyone's field of vision with the development of inertial technology. They are an important branch of the development of inertial technology. Their broad application fields determine its huge market in the future. This article mainly discusses the specific application of north finders in mining drilling.

In order to improve the safety of coal mines and strengthen the prevention and control of gas disasters and water damage in coal mines, drilling technology is one of the most effective methods. The quality of the hole formation determines the effectiveness and safety of the drilling technology. The opening accuracy of the borehole determines the quality of the borehole. Therefore, accurately measuring the opening posture of the borehole can help prevent and control coal mine gas and water damage, and ensure mining safety to a certain extent.

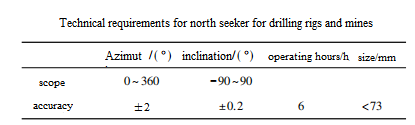

The drilling rig drilling measurement parameters mainly include azimuth angle and inclination angle. At present, the commonly used translation tunnel centerline method requires the use of rulers and goniometers, etc., which is complex to operate, takes a long time to measure, and has poor accuracy. For special applications in coal mines, comprehensive considerations such as cost and development difficulty must be taken into consideration while ensuring the actual measurement accuracy of drilling rig openings. Moreover, the drilling site space for underground coal mine construction is small, and the instrument must be easy to install and disassemble. Therefore, the structure and size of the instrument must be small, but at the same time, it must meet the requirements of battery size and capacity. In view of the above construction environment and actual needs, the technical requirements in Table 1 are put forward for mining north seekers.

Using process

During drilling construction, the drilling rig arrives at the designated drilling site. According to the designed azimuth and inclination angles, the operator can roughly predetermine the drilling rig's azimuth and inclination angle, and then place north finder at a relatively horizontal place near the drilling site to perform the north seeking operation. In the north-seeking system, an acceleration sensor is installed on the coordinate axis of the core component to measure acceleration, and a gyroscope is installed to measure the angular velocity component of the earth's rotation.

After the north search is completed, place the instrument on the guide rail of the drilling rig. At this time, the MEMS gyro strapdown inertial navigation system continuously measures, uses the strapdown inertial navigation solution to obtain the attitude angle, displays the current drilling rig attitude information in real time, and then adjusts the drilling rig attitude until the drilling rig attitude is reached. When the designed angle is reached, the hole orientation is completed.

Products advantages

1.Technical advantages:

(1) The north-seeking system is an important part of the directional plan for drilling openings. It provides the azimuth reference for the entire plan, and its north-seeking accuracy determines the overall accuracy of the plan. For the measurement of azimuth angle, due to the interference of ferromagnetic materials around, the inertial measurement method based on magnetic sensors used for drilling rig trajectory measurement cannot be used, so at this time, an instrument with good antimagnetic effect is needed to work properly.

(2) Measurement while drilling saves time and effort and reduces losses; wireless handheld control makes the operation simple and easy to learn; drilling data and trajectories can be displayed downhole, and drilling quality can be evaluated to improve work efficiency;

2. Installation advantages: On-site staff can operate the system proficiently without special training. It is also easy to install and can be mounted on a pre-positioned drill rig.

Summary

All in all, the use of a north-seeking directional meter can more accurately grasp the changes in the inclination and azimuth angle of the borehole, and facilitate the understanding of the distribution of blank zones outside the borehole control range, so that targeted supplementary measures can be taken. The promotion and application of inertial measurement technology in coal, drilling and other industries provides a new idea for industry positioning and orientation measurement. If you are interested in the directional technology of our north finder, welcome to learn about our Cost-efficient Triaxial MEMS north seeker and Smallest Size MEMS north seeker.

More Technical Questions

1.System Analysis of MEMS North Seeker

2.How to Process the Data of FOG North Seeker

3.Research on Anti-environmental Interference of North Finder

4.Analysis and Calibration of North Seeker Transposition Error

5.Analyze the Software Design of North Finder

6.Technical Analysis of FOG North Finder in Improving Accuracy

Products in Article