ER-MNS-05AD Dynamic MEMS North Seeker for Heading Machine

Introduction

The ER-MNS-05AD dynamic north seeker uses the latest MEMS gyro technology to achieve a perfect balance between size and performance. Its compact size makes it easy to adapt to various compact equipment and complex systems, and is suitable for scenarios that are sensitive to space and weight. It is mainly used in mining engineering, underground excavation, construction and other fields, and can be integrated into engineering machinery such as tunneling machines and mining equipment.

Unlike traditional measurement equipment that relies on magnetic fields, the high-precision MEMS gyroscope built into the north finder accurately measures the angular velocity component of the earth's rotation, and can achieve accurate measurement of the geographic true north direction without being affected by the magnetic field.

Using three-axis MEMS gyroscopes and three-axis MEMS accelerometer strapdown inertial measurement technology, the all-solid-state structure eliminates the risk of mechanical wear, and combined with the inner platform design, the impact and vibration resistance is far superior to traditional mechanical gyroscopes. It can withstand the vibration and shock environment common in mining operations to ensure stable operation of the equipment.

It adopts modular design, supports OEM customized development, has ample internal space and strong expandability. Whether it is used to upgrade existing equipment or develop new projects, it can flexibly meet diverse needs, effectively reduce integration costs and shorten development cycles.

Technical Features

- Adopt the latest MEMS gyro technology, compact size, 70×65×45mm (with shell)/43.2×43.2×35.5 mm (inner table);

- Adopt the latest three-axis MEMS gyro, three-axis MEMS accelerometer strapdown inertial measurement technology;

- Full solid-state design, built-in inner table, excellent impact and vibration resistance, and resistant to harsh environment;

- Modular design, OEM, strong scalability;

- With self-seeking function, not affected by magnetic field;

- 5°C to 55°C temperature compensation;

Applications

Direction of advanced mining/drilling equipment

Excavation operations in underground tunnels of coal mines, metal mines, etc., suitable for large equipment such as cantilever tunneling machines and continuous coal miners

Orientation and attitude measurement of transportation equipment such as mining AGV in underground tunnels

Precision platform attitude measurement and control

North search in land surveying/geological exploration

Specifications

| Model No. | ER-MNS-05AD |

| Azimuth accuracy (1σ,°secψ) | 1 |

| Attitude accuracy(1σ,°) | ≤0.3 |

| Azimuth accuracy retaining time | 20min |

| Attitude accuracy retaining time | 20min |

| Azimuth measurement range(°) | 0~360 |

| Inclination angle measurement range(°) | -85~85 |

| North seeking time | 180s |

| Update Rate (Hz) | 100 |

| Environment and power | |

| Operating temperature (℃) | 5~+55 |

| Storage temperature (℃) | 0~+65 |

| Power supply (V) | 6~12 DC |

| Power (W, power supply 6V) | 2 |

| Communication interface | RS-422 |

| Physical characteristics | |

| Size (mm×mm×mm) | 70*65*45(with shell)/43.2*43.2*35.5 (without shell and baseboard) |

| Weight (g) | ≤220(with shell)/≤100g (without shell and baseboard) |

Wiring Definition

| Connect Type | Pin | Definition |

| J30J-15ZKP | 1 | +6~12V |

| 3 | GND | |

| 6 | Tx+ | |

| 7 | Tx- | |

| 8 | Rx+ | |

| 9 | Rx- | |

| 10 | GND |

Dimension

Data protocols

Upper computer receiving protocol

The data update rate is 100Hz, the baud rate is 230400bps, and each frame contains 61 bytes of data, each byte contains 1 start bit (0), 8 data bits, 1 stop bit (1), and no parity. The specific data format is shown in the table below:

Table 1 Receive data frame format

| Bytes (60 bytes total) | Data content | supplementary note |

| 1~4 | header | EB8055AA |

| 5~8 | X Gyro Data | Low then high, dimensionless digital FLOAT |

| 9~12 | Y gyro data | Low then high, dimensionless digital FLOAT |

| 13~16 | Z Gyro Data | Low then high, dimensionless digital FLOAT |

| 17~20 | X ACCL data | Low then high, dimensionless digital FLOAT |

| 21~24 | Y ACCL data | Low then high, dimensionless digital FLOAT |

| 25~28 | Z ACCL data | Low then high, dimensionless digital FLOAT |

| 29~32 | Lon | Low then high, 0.000001°. |

| 33~36 | Lat | Low then high, 0.000001°. |

| 37~40 | Alt | First low, then high, 0.000001m |

| 41~44 | count | Low then high, 10ms |

| 45~46 | pit | Low then high, 0.01° |

| 47~48 | rol | Low then high, 0.01° |

| 49~50 | yaw | Low then high, 0.01° |

| 51~52 | North speed | First low then high, 0.01m/s |

| 53~54 | up speed | First low then high, 0.01m/s |

| 55~56 | east speed | First low then high, 0.01m/s |

| 57 | state | 0xA1 alignment, 0xB1 hold |

| 58 | end of frame | 0x00 |

| 59 | end of frame | 0xFF |

| 60 | end of frame | 0x34 |

| 61 | matching test | EB 80 and the sum of all bytes other than itself |

Host computer sending protocol

Total number of bytes sent down in a single transmission: 21 bytes, baud rate 230400bps, no parity, each byte includes: start bit (0), data bit (8 bits), stop bit (1).

- Priming

| byte symbol | define | note |

| 1 | 0xEB | |

| 2 | 0x80 | |

| 3 | 0x00 | |

| 4 | 0xCC | |

| 5-8 | 0x00 | |

| 9-12 | 0x00 | |

| 13-16 | 0x00 | |

| 17-21 | 0x00 |

- Send warp and woof height

| byte symbol | define | note |

| 1 | 0xEB | |

| 2 | 0x80 | |

| 3 | 0x00 | |

| 4 | 0xAA | |

| 5-8 | lon | |

| 9-12 | lat | |

| 13-16 | alt | |

| 17 | 0xAA | |

| 18 | 0xBB | |

| 19 | 0xCC | |

| 20 | 0xDD | |

| 21 | 5~20 heterodyne calibration |

Determine the definition of the data sent based on byte 4:

- if control_flag==0xCC: restart work

- if control_flag==0xAA: send latitude/longitude altitude

Send order: 5-8 bytes: latitude (*1e6 in °)

9-12 bytes: longitude (*1e6 in °)

13-16 bytes: height (*1 in m)

For example, the C code that sends the latitude/longitude instruction (the rest of the bytes are configured arbitrarily), Latitude is "latitude * 1e6", longitude is similar, and altitude scale is 1.

bytSend[0] = 0xeb;

bytSend[1] = 0x80;

bytSend[2] = 0x00;

bytSend[3] = 0xaa;

bytSend[4] = (Latitude>>24) & 0xff;

bytSend[5] = (Latitude>>16) & 0xff;

bytSend[6] = (Latitude>>8) & 0xff;

bytSend[7] = (Latitude) & 0xff.

bytSend[8] = (Longitude>>24) & 0xff;

bytSend[9] = (Longitude>>16) & 0xff;

bytSend[10] = (Longitude>>8) & 0xff;

bytSend[11] = (Longitude) & 0xff.

bytSend[12] = (Altitude>>24) & 0xff;

bytSend[13] = (Altitude>>16) & 0xff;

bytSend[14] = (Altitude>>8) & 0xff;

bytSend[15] = (Altitude) & 0xff;

bytSend[16] = 0xaa;

bytSend[17] = 0xbb;

bytSend[18] = 0xcc;

bytSend[19] = 0xdd;

bytSend[20] = b[4]^b[5]^... .b[19];

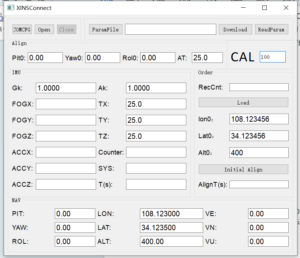

Introduction to the software

Click the COMCFG button to set the serial port, baud rate and frequency. The baud rate is 230400 and the frequency CAL is 100HZ.

Click Open to start the test.

Click Initial Align to start the north search, the search time is 300s.The result is displayed at PIT;YAW;ROL.

If you want to change the latitude and longitude, please change them at Lon0 and Lat0, then click Load, and then click Initial Align to re-navigate.

After sale

Please do not disassemble this product without our company's permission, if disassembled without permission, the warranty will be invalid.

If there is any technical problem or failure in the use of the product, you can contact the corresponding technical personnel of our company.

Application Techniques

1.Applicable to coal mines, tunnels, and exploration! North seeker's strength revealed

2.How important is the North Seeker in the field of oil、mining and drilling?

4.Efficient mining, north seeker assists mining drilling operations

5.Accurate orientation, easy to deal with! North seeker helps work more efficiently