Drilling and logging operations have high requirements for directional and wellbore trajectory control. Traditional fiber optic gyroscopes and magnetic inclinometers are large in size, weak in anti-interference ability, and high in cost. MEMS gyroscopes have become core components for drilling and logging due to their miniaturization, high reliability, and environmental adaptability.

Navigation-grade MEMS gyroscopes are the best alternatives to low- and medium-level navigation-grade FOG and DTG. For example, ER-MG2-50, with a range of ±50°/s, 0.01°/hr zero bias instability, and 0.0025°/√hr angular random walk, is designed for north-seeking applications. The advanced differential sensor design can effectively suppress the influence of linear acceleration and will not be damaged in extremely harsh environments with shock and vibration.

Compared with traditional gyroscopes and inclinometers, MEMS gyroscopes have irreplaceable advantages in downhole applications:

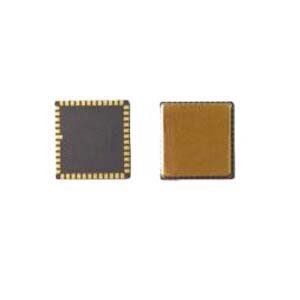

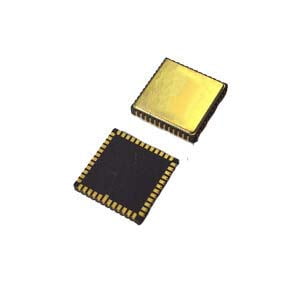

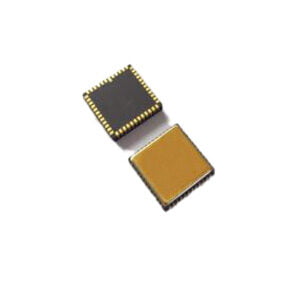

Miniaturization and low power consumption: ER-MG2-50 adopts the latest MEMS technology, with a miniature size (11x11x2mm), light weight, easy to integrate into space-constrained downhole instruments (such as MWD/LWD tools, logging instrument strings), and extremely low power consumption.

High shock and vibration resistance: MEMS structure is insensitive to harsh downhole environments (such as severe vibration and shock), and can withstand 12grms (20Hz-2kHz) random vibration. Strong stability and high reliability.

Cost-effectiveness: The cost is much lower than high-precision FOG/DTG.

**MWD and trajectory control**

Wellbore trajectory control is the core application of MEMS gyroscopes in drilling. It is usually integrated into MWD/LWD tools with three axes, continuously measuring the rotational angular velocity of the borehole assembly (BHA) on three orthogonal axes. Combined with accelerometers, it can solve the well inclination, azimuth and tool face angle in real time.

**Not affected by magnetic fields**

Under magnetic interference (casing, iron ore layer, adjacent wells), magnetic inclinometers that rely on the geomagnetic field will fail or have large errors. The MEMS gyroscope ER-MG2-50 calculates the true north direction by measuring the angular velocity component, does not rely on the geomagnetic field, can provide accurate azimuth information, and is the best choice in magnetic environments (called "gyro MWD").

Application Techniques

1.Basic Knowledge of Bias Stability of MEMS Gyroscope

2.Classification And Performance Improvement Of MEMS Gyroscope

3.Comparison Of Technical Specifications Of Navigation Grade MEMS Gyroscope

4.MEMS Gyroscope: The Third Generation Of Gyroscopes Is Leading The Way

5.MEMS Gyroscope: Sensitive Structure | Detection Circuit | Integrated Package

6.Research On Segmented North Seeking Orientation Based On MEMS Gyroscope