In the fields of oil and gas logging, directional drilling and pipeline engineering, traditional directional measurement equipment based on fluxgate sensors often suffers from metal environments such as casing and drill pipes or abnormal interference from the geomagnetic field, which greatly reduces the azimuth measurement accuracy or even makes it unable to work.

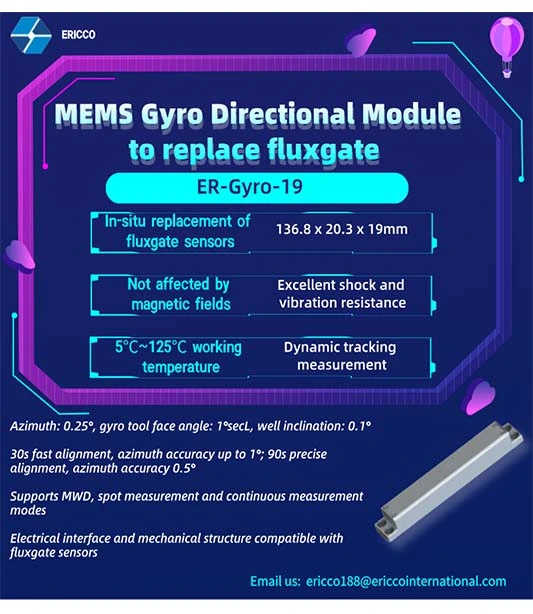

In response to this industry pain point, ERICCO has created the ER-Gyro-19 MEMS gyro directional module that can achieve measurement while drilling or continuous measurement, becoming the industry's first directional solution that can replace fluxgate sensors in situ.

In-situ replacement of fluxgate sensor technology

ER-Gyro-19 is equipped with a high-precision MEMS gyroscope with self-seeking function. It uses the fusion algorithm of three-axis MEMS gyroscope and accelerometer to realize dynamic continuous tracking measurement of well inclination, tool face angle and azimuth, supports MWD, point measurement and continuous measurement mode, and can collect drilling trajectory data in real time.

The electrical interface and mechanical structure compatible with the fluxgate sensor are adopted, and it can be directly replaced in-situ without modifying the hardware architecture of the probe or logging equipment, which greatly reduces the equipment modification cost and installation complexity.

Achieve precise measurement

The azimuth accuracy can reach up to 0.25°secψ (1σ), the gyro tool face angle accuracy is 1°secL (L is latitude), and the well inclination alignment accuracy is 0.1° (1σ).

30s fast alignment, azimuth accuracy of 1°; 90s precise alignment, azimuth accuracy of 0.5°, significantly shortening the downhole operation preparation time.

The azimuth and gyro tool face angle measurement range is 0~360°, the gravity tool face angle measurement range is -180~180°, and the well inclination measurement range is 0~90°, which can easily cope with a variety of operation scenarios.

Extremely miniaturized design

Adopting the latest MEMS gyro technology, it subverts the size of traditional gyro tools and is extremely small, only 136.8 x 20.3 x 19mm, which can be easily embedded in the narrow front-end space such as the probe tube, and is suitable for small-diameter drilling operations.

Not affected by magnetic fields

ER-Gyro-19 does not require external magnetic reference or manual calibration. It relies on the gyro itself to sense the rotation of the earth, measure the earth's rotation angle component, and then calculate the north information. It does not rely on external information to find the north, fundamentally solves the problem of magnetic field interference, and maintains stable measurement accuracy in extreme scenarios such as cased wells and magnetic mining areas.

Strong environmental adaptability

Adopting the latest three-axis MEMS gyro and three-axis MEMS accelerometer strapdown inertial measurement technology, it has good stability and high reliability.

All-solid-state design, no mechanical moving parts, excellent shock and vibration resistance, meeting the harsh environmental requirements of drilling conditions.

5℃~125℃ full temperature calibration compensation, combined with temperature drift compensation algorithm, ensures measurement stability in the full temperature range and adapts to extreme environments.

The ER-Gyro-19 MEMS gyro directional module has three core advantages: "in-situ replacement, anti-magnetic interference, and high-precision dynamic measurement", which solves the technical bottleneck of traditional magnetic measurement tools under complex working conditions. Its miniaturization, all-solid-state and wide temperature range design promotes the deep penetration of inertial measurement technology in the field of industrial guidance, and is gradually becoming a new industry standard to replace fluxgate sensors.

Application Techniques

1.Basic Knowledge of Bias Stability of MEMS Gyroscope

2.Classification And Performance Improvement Of MEMS Gyroscope

3.Comparison Of Technical Specifications Of Navigation Grade MEMS Gyroscope

4.MEMS Gyroscope: The Third Generation Of Gyroscopes Is Leading The Way

5.MEMS Gyroscope: Sensitive Structure | Detection Circuit | Integrated Package

6.Research On Segmented North Seeking Orientation Based On MEMS Gyroscope