In tunnel construction, mining, underground engineering, and other fields, accurate orientation of a TBM is directly related to project efficiency, safety, and cost control. Traditional orientation technology often relies on static measurements, and once the equipment begins to move or turn, orientation accuracy becomes difficult to maintain. So, can a TBM achieve continuous and accurate orientation while moving or turning? The answer is yes—with the ER-MNS-05A dynamic MEMS north finder, the TBM can not only achieve high-precision initial alignment but also maintain stable orientation tracking in dynamic environments.

Why is dynamic orientation of a TBM a major technical challenge?

TTBs often face complex operating conditions such as vibration, inclination changes, and sudden turns. Traditional orientation equipment performs well in static environments, but is susceptible to interference in dynamic conditions, resulting in drift in orientation data, reduced accuracy, or even complete failure. Furthermore, the TBM's body structure undergoes significant angular changes during turns. If the orientation system cannot respond in real time, the accuracy of the construction trajectory will be seriously affected.

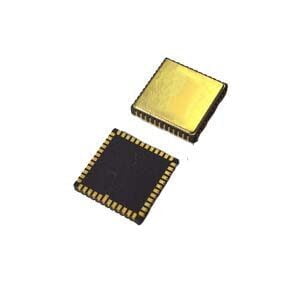

ER-MNS-05A: A high-performance north-finding solution designed for dynamic environments.

The ER-MNS-05A is a dynamic north-finding device based on MEMS (micro-electromechanical systems) technology, offering both static high-precision alignment and dynamic continuous tracking. Its core advantages include:

High-precision static alignment

When stationary, the ER-MNS-05A achieves an azimuth accuracy of less than 1° (within 30 seconds), providing a reliable initial reference orientation for the roadheader. This performance far exceeds that of most traditional sensors, laying a solid foundation for subsequent dynamic tracking.

Excellent dynamic holdover performance

Even while the roadheader is moving or turning, the device can maintain 0.5° tracking accuracy for up to 20 minutes. This means the roadheader can continuously obtain accurate azimuth data without frequent downtime for calibration, significantly improving operational efficiency.

Strong anti-interference capability

Through advanced algorithm compensation and sensor fusion technology, the ER-MNS-05A effectively suppresses the effects of environmental factors such as vibration, temperature fluctuations, and electromagnetic interference, ensuring stable and reliable data output.

Technical Principle: How does it achieve dynamic continuous orientation?

The ER-MNS-05A utilizes a multi-sensor fusion architecture, combining a three-axis MEMS gyroscope and accelerometer to calculate azimuth in real time using Kalman filtering and adaptive algorithms. Its workflow includes:

Initial north-seeking: Rapidly determine true north in static environments;

Dynamic tracking: Once the device begins moving, the system automatically switches to tracking mode, integrating gyroscope data to update azimuth in real time;

Error compensation: Utilizing accelerometer data to correct gyro drift, ensuring long-term accuracy.

This technical approach ensures both initial alignment accuracy and sustained orientation in dynamic environments.

Summary: Precise orientation is no longer limited to static conditions.

Sustained and accurate orientation of tunnel boring machines during travel and reversal was once a technical pain point for many companies. The ER-MNS-05A dynamic MEMS north-seeker, through its innovative design and algorithm, successfully overcomes this bottleneck. It not only provides high-precision north-seeking in static conditions but also enables reliable orientation tracking in dynamic environments, providing key technical support for the intelligent and efficient operation of underground engineering equipment.

If you're looking for an orientation solution that's both accurate and stable for complex working conditions, the ER-MNS-05A is your ideal choice.

Application Techniques

1.Why can MEMS north finders become the revolutionary orienteering in the era of miniaturization?

2.How important is the North Seeker in the field of oil、mining and drilling?

3.ER-MNS-09 MEMS directional module: a precise tool for revolutionizing drilling technology

4.Precision without boundaries! ER-MNS-05 MEMS North Finder defines new mining standards

6.Efficient mining, north seeker assists mining drilling operations

More Products