With the increasing demand for intelligent and automated mining projects, accurate geographic orientation perception has become a core element to ensure the efficiency and safety of underground operations. The ER-MNS-05 MEMS North Finder provides an innovative solution for the orientation of mining equipment with its all-solid-state design, high-precision measurement and adaptability to harsh environments.

Core technology advantages: all-solid-state MEMS architecture and shock-resistant design

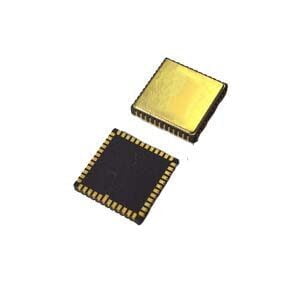

The core technology of ER-MNS-05 is based on a strapdown inertial measurement system of a three-axis MEMS gyroscope + a three-axis MEMS accelerometer. Compared with traditional mechanical gyroscopes, it adopts an all-solid-state design with no moving parts, which fundamentally avoids mechanical wear problems and significantly extends its life. Through temperature compensation algorithms (5°C to 55°C) and anti-vibration structure optimization, the equipment can maintain heading accuracy (up to 0.25°secψ) and attitude accuracy (≤0.2°) in strong vibrations (such as blasting, mechanical shock) and temperature changes commonly seen in mining operations.

Volume and weight optimization is another highlight: the inner platform size is only 43.2×43.2×35.5 mm, the weight is ≤100g, and it supports housing-free installation, which greatly improves the flexibility of equipment layout, especially for underground tunnel equipment with limited space (such as mining AGV, compact tunneling machine).

Core applications for mining scenarios

1. Tunneling equipment pointing control

In tunneling in coal mines and metal mines, cantilever tunneling machines and continuous coal mining machines need to obtain the true north direction in real time to plan the tunneling path. ER-MNS-05 can dynamically correct the equipment heading deviation through static north-seeking mode (initialization is completed in 5 minutes) and 100Hz high-frequency data update, avoiding the problem of traditional magnetic sensors being interfered by underground metal structures, and ensuring the trajectory accuracy of long-distance tunneling.

2. Orientation and attitude measurement of transportation equipment

For the autonomous navigation needs of underground AGV, the device integrates inclination measurement (-85°~85°) and heading keeping function (20 minutes). Even in tunnels with frequent slope changes, it can still output attitude data in real time through the RS-422 interface to support path planning and obstacle avoidance decisions.

3. Precision measurement for exploration and construction

In geological exploration and land measurement, it is not affected by magnetic fields. Combined with the 0~360° omnidirectional heading coverage capability, a high-precision azimuth reference can be quickly established.

Engineering adaptability: modular and plug-and-play design

ER-MNS-05 adopts OEM modular architecture, which supports users to strip the shell and directly embed it into the host system according to their needs, significantly reducing the complexity of integration. Its 6~12V wide voltage power input and universal RS-422 communication protocol can seamlessly connect to mainstream engineering machinery controllers without relying on dedicated interfaces (such as traditional 15-pin plugs), shortening the equipment debugging cycle. In addition, the 2W low power consumption feature further meets the energy constraints of underground equipment.

Summary

The ER-MNS-05 MEMS north finder solves the bottlenecks of accuracy, stability and adaptability of traditional north finders in mining environments through technological innovation and engineering design, and provides key technical support for the autonomous upgrade of underground equipment.

Application Techniques

1.Applicable to coal mines, tunnels, and exploration! North seeker's strength revealed

2.How important is the North Seeker in the field of oil、mining and drilling?

4.Efficient mining, north seeker assists mining drilling operations

5.Accurate orientation, easy to deal with! North seeker helps work more efficiently