In harsh tunneling environments like mines and tunnels, accurate, fast, and reliable orientation is crucial for efficient and safe construction. Traditional equipment that relies on magnetic fields is susceptible to interference, and mechanical gyros are sensitive to vibration. The ER-MNS-05A dynamic MEMS north finder is designed to meet these challenges, using cutting-edge technology to reshape the "sense of direction" of tunnel boring equipment!

Core Pain Points and Solutions:

Pain Points: Magnetic field interference leading to inaccurate orientation? Mechanical gyros susceptible to vibration and damage? Time-consuming alignment affecting efficiency? Limited space and difficult installation?

Solution: The ER-MNS-05A features a built-in high-precision MEMS gyroscope that directly senses the Earth's rotation, completely eliminating reliance on magnetic fields! Its all-solid-state design is shock-resistant and vibration-resistant, making it specifically designed for the harsh working conditions of mines and tunnels.

ER-MNS-05A Dynamic MEMS North Finder for Roadheaders: The Ultimate Tool for Precise Orientation

The ER-MNS-05A is a north finder designed for demanding industrial environments such as mining, tunneling, and geological exploration. Leveraging the latest MEMS gyro technology, it achieves astonishingly high accuracy, speed, and exceptional stability in an extremely compact package. It is key to improving the orientation of large construction machinery (such as boom roadheaders and continuous miners) and transport equipment (such as automated guided vehicles for mining).

Why is the ER-MNS-05A the best choice for your tunneling operations?

⚡️ Ultra-fast and precise orientation, doubling efficiency:

Static alignment with 1° accuracy in 30 seconds significantly reduces equipment startup wait time.

Precise alignment in 90 seconds achieves 0.5° azimuth accuracy, providing a reliable benchmark for critical operations.

Dynamic tracking and retention accuracy: 0.5°/20 minutes provides a stable and reliable orientation reference even during movement or vibration, ensuring precise tunneling trajectory.

?️ High stability, resistant to harsh environments:

Core advantages: All-solid-state design + internal platform structure. Completely eliminates the risk of mechanical wear.

Excellent shock and vibration resistance easily withstands the intense vibration and shock inevitably encountered in mines and tunnels, ensuring long-term stable operation under extreme working conditions.

Wide operating temperature range (5°C to 55°C) with built-in temperature compensation adapts to complex underground temperature fluctuations.

? True North Measurement, Immune to Magnetic Field Interference:

Directly determines geographic true north direction based on measuring the Earth's rotational angular velocity.

Completely immune to interference from strong magnetic fields and ferromagnetic materials at the worksite, this sensor overcomes the critical weakness of traditional magnetic sensors in mines and equipment, ensuring reliable orientation results.

? Extremely compact, worry-free integration:

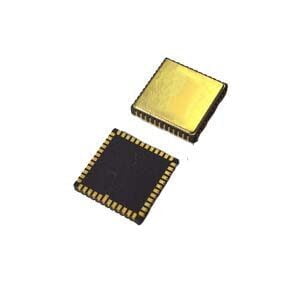

Amazingly small size: The core module measures only 43.2 × 43.2 × 35.5 mm (excluding the housing); with the housing, it measures only 70 × 65 × 45 mm. Lightweight at ≤100g (core) / ≤220g (with housing).

Designed for integration within space- and weight-sensitive construction machinery, it easily fits into tight spaces.

? Modular Design, Flexible Expansion:

Standardized OEM modular design provides clearly defined interfaces (RS-422).

Ample internal space and strong expandability facilitate secondary development or customized integration.

Significantly reduces integration costs and shortens development cycles, making it suitable for both new equipment development and upgrades to existing equipment.

Exceeding Performance, a Reliable Partner:

The ER-MNS-05A is the intelligent core that ensures precise, efficient, and safe operation of roadheaders, mining equipment, or transport AGVs. Its three-axis MEMS gyroscope and three-axis MEMS accelerometer strapdown inertial measurement system not only provides precise orientation (0-360°) but also high-precision attitude information (pitch/roll ≤0.2°, range ±85°), meeting more complex measurement needs.

Application Techniques

1.Why can MEMS north finders become the revolutionary orienteering in the era of miniaturization?

2.How important is the North Seeker in the field of oil、mining and drilling?

3.ER-MNS-09 MEMS directional module: a precise tool for revolutionizing drilling technology

4.Precision without boundaries! ER-MNS-05 MEMS North Finder defines new mining standards

6.Efficient mining, north seeker assists mining drilling operations