Mineral resources is one of the basic industries. With the depletion of shallow resources and the gradual development of mineral resources to the deep, the number of deep Wells will be greatly increased. Due to the increase of well bore depth, the increase of well bore water and the increase of ambient temperature, the traditional geometric orientation difficulties are greatly increased, and the accuracy cannot be guaranteed. Gyroscope orientation has important practical significance for ensuring the quality of important underground projects, reducing the time occupied by the shaft, ensuring the safety of mine production, reducing the work intensity of surveyors and improving the economic benefits of enterprises.

The gyroscope orientation does not need to occupy the well bore, the preparation work is simple, and the orientation accuracy is high. The error in a single orientation is between 5"~2', and ER-MG2-50/100 has 0.01-0.02°/hr bias instability and 0.0025-0.005°/√hr angular migration, which can fully meet the accuracy requirements of various mining engineering. In addition to the poles and high latitudes (above 75°) on the earth, the true meridian position and geodetic azimuth of any measuring station on the ground or underground can be determined, and the orientation accuracy is not affected by the depth of the shaft. In addition to the checkeable and alternative geometric orientation, when the through wire is very long, the directional attachment wire can be improved by properly adding the directional edge of the gyroscope. With the increasing number of mining in deep Wells, gyroscopic orientation will be rapidly popularized.

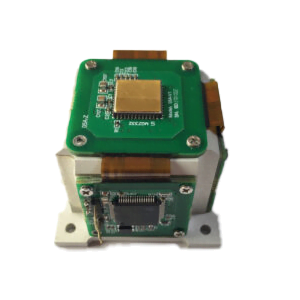

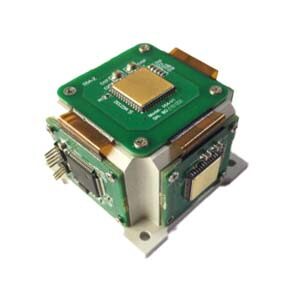

Compared with the gyroscope used in aviation, the gyroscope used in logging has the following characteristics due to the influence of its operating environment. First of all, the volume requirements are strict, especially the diameter is small, and the instrument is required to adapt to the diameter requirements of the casing well after formation, and even can be invested from the drill pipe when opening the skylight; Second, it has strong vibration resistance, which will not damage the gyro body when the test drilling is opened or put into the bottom hole. There is also a wide temperature requirement, that is, the instrument can work normally in an environment of 125°C for at least 2 hours and in the ambient temperature range of -10~125°C. The ER-MG2-022 high temperature North seeking MEMS gyro is the best choice, with 0.025°/√h angular migration and 0.1°/hr bias stability in addition to the temperature required in the mining field, and the overall accuracy meets the requirements of logging tools.

Application of gyroscopic orientation in coal mine

Gyro azimuth method in tunnel driving

Under normal circumstances, in the process of underground excavation, the task of roadway excavation is completed by wire. However, in the later period of construction, because the roadway has not formed a ring, so at this time, only the branch wire can be used to control the direction of excavation, the error of the branch wire accumulates quickly, and it is difficult to ensure the accuracy requirements when the roadway is long. Therefore, we can use the method of measuring the azimuth of the gyroscope in the process of driving, and this method has also achieved good results in the actual production process. Adding a gyroscope edge - generally there are three methods: first, add a gyroscope edge at the last edge of the branch wire to form an attached wire; Second, each edge is added to measure the gyro azimuth, this form is also called gyro wire; Third, two top edges are separated on the branch wire to form two echo wires.

Gyroscope fast orientation method

All surveying and mapping projects are called mining area surveying and mapping in the early mining period to the completion of mining. The key point of mining area surveying and mapping is the contact surveying and mapping of mining area. Due to the short mining roadway, small mining retting range and poor working conditions, the measurement accuracy of general mining area is not high. The traditional method is mainly the compass wire, but the previous problem is that there is no magnetic influence, the compass can not be used in the roadway with magnetic influence, and the patio geometric orientation is still used, which is time-consuming and laborious, and the accuracy is difficult to guarantee. The fast orientation method with gyroscope and the observation method with two reverse points are very effective.

Application of gyroscope in shaft orientation survey

During the entire operation. With the development of the entire construction process, the excavation work gradually develops to the deeper bottom, the difficulty of the entire project will gradually increase, and the use of gyroscope instruments at this time will achieve the effect of saving time and labor, and the safety risks will also be reduced. First, the constants of the three instruments are found and determined on the surface, and then the positions and directions of the two gyros are determined on both sides of the fixed directions in the well. Return to the well to measure the three constants that have been determined, and the entire operation process should be controlled within three days. The difference between the gyroscope azimuth Angle must not exceed the specified range.

More Technical Questions

2.How accurate is MEMS gyroscope?

3.Where are MEMS Gyroscopes Used?

5.Do you know several north seeking schemes used in gyroscopes?

6.What Data Format is High Performance MEMS Gyro

Products in Article

.jpg)