MEMS north seekers have great application prospects in the field of inertial north finders. Compared with traditional gyro north finders, MEMS gyro north seekers have relatively low accuracy, but their cost advantages are obvious. In addition, size, weight and power are also highlights, which can shorten the gap between low-cost north finders and small, low-weight, low-power portable devices.

1. Why does temperature affect the MEMS north seeker?

The MEMS gyroscope built into the north-seeking device is a temperature-sensitive device, and its material is semiconductor silicon. When the temperature changes, the thermal expansion coefficient, elastic modulus, resonant frequency of the silicon wafer will change. The zero bias and scale factor of the MEMS gyroscope will be affected by the temperature characteristics. During underground operations, complex environmental temperature changes Will affect the performance of MEMS gyroscope. Temperature will affect the size and structure of the gyroscope's head, the performance of the components, the elastic modulus of the material and the resonant frequency, etc., thereby affecting the zero bias and scale factor of the MEMS gyroscope. Since the materials and electronic components of the gyroscope are very sensitive to temperature changes, the measurement accuracy of the MEMS gyroscope will be severely restricted. As the core component of the north-finding device, the gyroscope will have an important impact on the accuracy of the north finder.

2. Bias temperature compensation technology of MEMS north seeker

The implementation of underground north-seeking operations based on the three-axis MEMS north-seeking instrument needs to overcome the complex underground environment, such as temperature, vibration, etc., which will affect the measurement accuracy of the MEMS north-seeking instrument. Temperature is one of the main factors affecting the performance of three-axis MEMS north-seeking equipment, mainly affecting its zero offset. Therefore, in order to improve the measurement accuracy of north-finding, it is necessary to establish a compensation model for the zero-bias temperature change. However, effective compensation can improve its accuracy and help expand the application range of north-finding equipment. Generally speaking, there are two solutions for temperature compensation: one is to install a constant temperature device on the north-seeking system and control the circuit to enable the equipment to operate normally at a stable temperature; the other is to use software algorithms to achieve compensation. The relationship between zero deviation and temperature changes is obtained through mathematical models. For now, the above two temperature compensation methods are in use. The first compensation method uses a thermostat to set a constant temperature to maintain the working environment at a constant temperature state. This method requires a lot of time, and increases the volume and cost. In the field of well logging, it is developing in the direction of small well diameter, low cost, high precision and rapid north search. Therefore, solutions that increase volume and cost are not advisable. The second method is to compensate by using mathematical models, which is gradually replacing the first method as the main means of zero-bias temperature compensation, such as: least squares method, gray prediction, neural network prediction, etc.

This paper analyzes the original bias data of the three-axis MEMS north seeker, uses an improved gray prediction model to temperature compensate the Y-axis bias in the three axes, and uses the least squares method to temperature compensate the X and Z-axis bias. It can improve the accuracy of MEMS north finder.

3. Experimental results:

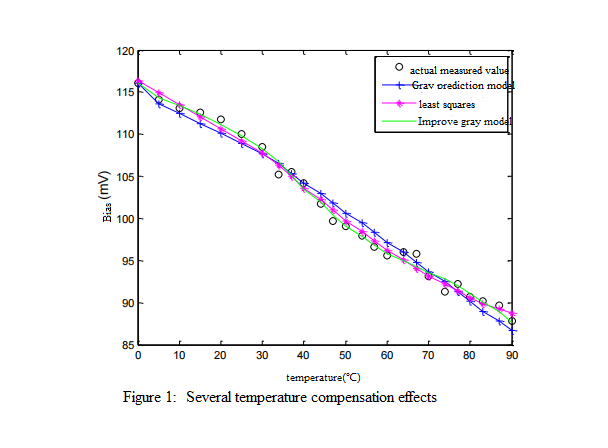

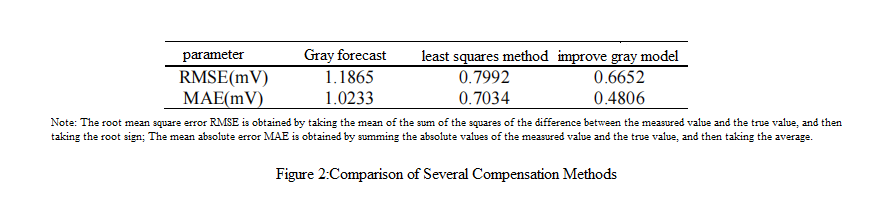

As can be seen from Figure 1, compared with gray prediction and least squares method, the Y-axis bias value obtained by the improved gray prediction model is closer to the measured value. As can be seen from Table 2, the root mean square error (RMSE) and mean absolute error (MAE) of the zero bias obtained by least squares fitting are 0.7992 mV and 0.7034 mV respectively, predicted by gray The RMSE and MAE of the zero-bias predicted by the model are 1.1865 mV and 1.0233 mV respectively, while the RMSE and MAE of the bias obtained by the improved gray prediction model are 0.6652 mV and 0.4806 mV respectively. The results show that the RMSE and MAE of the improved gray model are smaller. . Compared with the conventional compensation model, the improved gray prediction model can better compensate for the drift of the Y-axis zero bias with temperature.

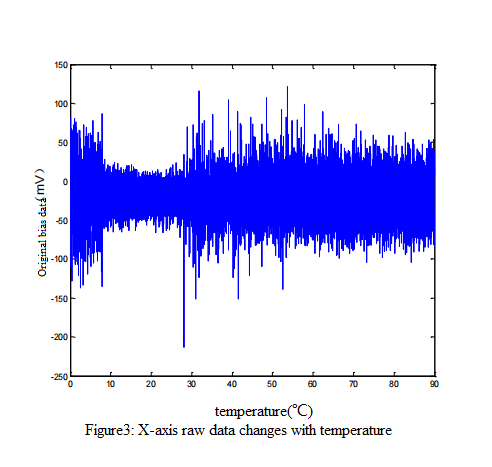

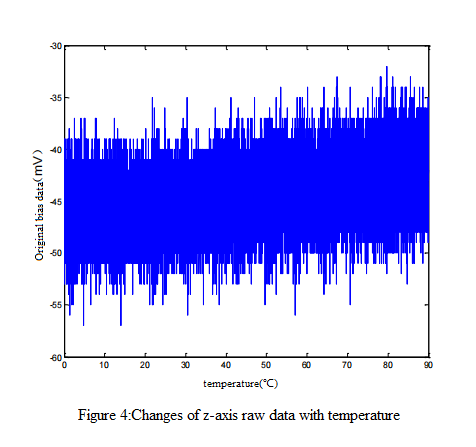

For the X-axis and Z-axis, nearly 50000 pieces of data were collected respectively in the temperature range of 0°C to 90°C. Their original data changes with temperature are shown in Figures 3 and 4 respectively.

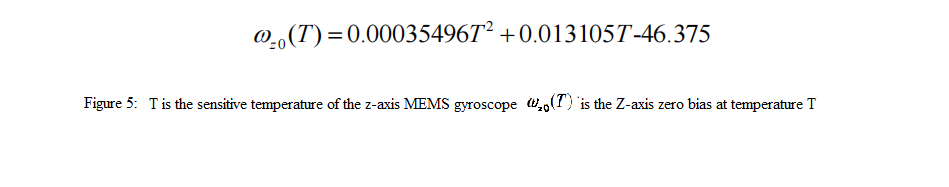

It can be seen from Figure 3 that the zero-bias data of the X-axis oscillates around a fixed value and exhibits large fluctuations due to the influence of noise. Therefore, the influence of the temperature X-axis on the zero-bias can be ignored and presented as a fixed value.wx0 =-22.5775 mV. For the Z-axis in Figure 4, the zero offset can be temperature compensated through the least squares method. Z-axis offset temperature compensation model:

4. Summary:

Ericco is constantly experimenting with the parameters of inertial products to improve the quality and performance of its products. Through our continuous development and improvement, our MEMS three-axis north seeker not only has the function of full temperature compensation, but can also withstand harsh monitoring environments. , we even have the world's smallest Mems north seeker, which is very popular among customers. If you are interested in this, please feel free to contact us, and we will provide you with more professional answers.

More Technical Questions

1.Research on Signal Acquisition of Strap-down North Seeker

2.Technical Analysis of FOG North Finder in Improving Accuracy

3.Error Analysis and Compensation Technology of North Seeker

4.Introduction and features of MEMS north seeker

5.The Smallest Size MEMS North Seeker

6.How to Use Acquisition Software of MEMS North Seeker?

Products in Article