Impact is one of the most important factors affecting the reliability of MEMS gyroscope. Different from mechanical vibration stress, its acceleration amplitude is very high and the impact pulse width is small. The operating environment of most devices is 1g gravitational acceleration, but the device may withstand greater mechanical impact in the actual application environment. The mobile phone accidentally falls from a height of 1.2m, and according to the impact direction and impact surface, it can experience an acceleration of 500~5000g, the acceleration to be sensed by the car accelerometer reaches 100g, and the impact acceleration of the aerospace fire bolt used for inter-stage separation in the spacecraft is 10000g.

This paper will analyze the impact of shock on MEMS gyroscope, and propose new results and techniques to help MEMS gyroscope improve its shock resistance. The following will introduce the common faults caused by impact, the theoretical basis of impact protection structure and the design of impact protection structure.

Common faults caused by impact

1. Fracture caused by the stress caused by the impact exceeding the yield strength of the material

2. Static friction caused by the contact of components with each other

3. Particles, such as micron-sized particles, block or short-circuit the comb drive

4. Short circuit due to the contact of parts with different potentials

5. Packaging failure, such as interface stripping or air tightness failure

Theoretical basis of impact protection structure

In order to realize the high impact application of gyroscope, it is necessary to improve the impact resistance of the structure. The common anti-impact design methods include optimizing beam structure, adding barrier structure and supporting protection structure. Due to the special spring beam structure, the stiffness of the beam is increased, which can withstand high impact stress in different directions, and the gyroscope of the structure can also be used to resist high impact. The double-cascade elastic barrier structure is often used in MEMS accelerometers to improve its impact resistance. It has a stronger impact resistance than the cylindrical hard barrier structure, and can withstand the impact force with a pulse width of 100μs and a peak acceleration of 10000g.

It is pointed out that the support protection structure can improve the impact resistance. Although increasing the stiffness coefficient of the structure can increase the elastic recovery force and improve the impact resistance, it will reduce the sensitivity of the gyroscope. The design of various barrier structures can also improve the impact resistance, but the barrier structure may produce silicon slag during the impact, resulting in particle pollution. Therefore, it is best to increase the support protection structure to isolate the transmission of stress, reduce the impact stress of the structure, and prevent mechanical collisions between the structures.

Impact protection structure design

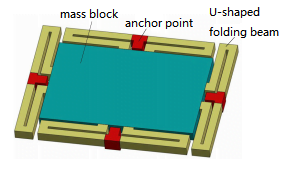

As shown in Figure 1, it is a second-order damped vibration structure, consisting of 8 U-shaped folded beams, 4 large anchor points and 1 large mass block. The structure is also machined based on silicon materials.

Figure 1 Impact protection structure model diagram

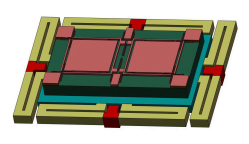

The gyroscope structure is fixed on the central mass block of the impact protection structure. The impact protection structure is generally silicon structure or printed circuit board (PCB), etc., and the fixed connection between the gyroscope structure and the impact protection structure can be realized through silicon-silicon bonding, silicon-glass bonding or viscose bonding, as shown in Figure 2. The gyro structure is based on the silicon-glass bonding (SOG) process, and its glass substrate is also held together with a large mass block of the impact protection structure by anodic bonding. The impact protection structure does not affect the natural frequency characteristics of the gyroscope. In order to reduce the influence of the silicon gyroscope structure on the motion characteristics of the impact protection structure, the mass can be increased by increasing the area or thickness.

Figure 2 MEMS gyroscope structure and impact protection structure bonding model diagram

Conclusion

This paper introduces the possible faults caused by shock to MEMS gyroscope, and proposes a shock protection structure based on theory. The impact structure can make the MEMS gyro better withstand the impact and improve its reliability. ER-MG2-50/100 as a high-performance north seeking MEMS gyroscope, it has high impact resistance, its impact is 1000g,1ms in the case of live, 10000g,1.0ms in the case of no live. Its excellent performance and performance can be applied to north finding, pointing, initial alignment of logging instruments, mining/drilling equipment, weapons/drone launch systems, and can also be applied to high temperature and harsh environments.

If you are interested in other knowledge of MEMS gyroscope, please contact us.

More Technical Questions

1.Error Analysis of MEMS Gyroscope

2.The analysis of damping in MEMS gyroscope

3.Noise Analysis and Solutions of MEMS Gyroscope

4.Wafer-level vacuum packaging of MEMS gyroscope chips

5.Research on scale factor nonlinearity of MEMS gyroscope

6.Research on driving mode of MEMS gyroscope

Products in Article