With the rapid development of MEMS technology, MEMS gyroscopes are increasingly used in the field of oil exploration. However, in actual exploration, as energy extraction becomes increasingly depleted, the difficulty of exploration and mining continues to increase, and the mission of gyroscopes is becoming more and more important.

The core components of mainstream exploration equipment on the market are generally dynamic tuning gyroscopes or fiber optic gyroscopes. First of all, the large size of these two gyroscopes limits their application scenarios. Secondly, the manufacturing process of dynamic tuning gyroscopes is complex, and the internal mechanical structure is precise and easy to damage. It is at risk of damage at any time under strong vibration and impact conditions. Due to the nature of the optical fiber itself, the fiber optic gyroscope is greatly affected by temperature, and it is difficult to exert its performance advantages under large temperature differences. In contrast, MEMS gyroscopes have stronger resistance to shock and vibration, are resistant to high temperatures, and can be applied in a wider range of fields.

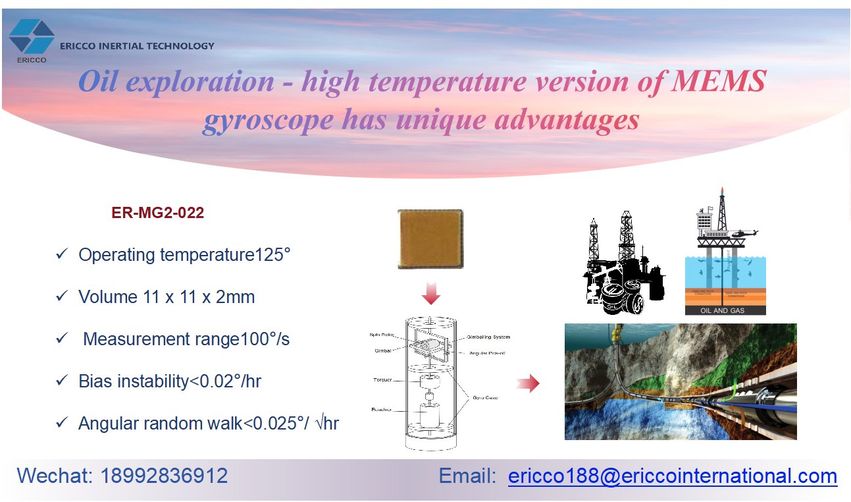

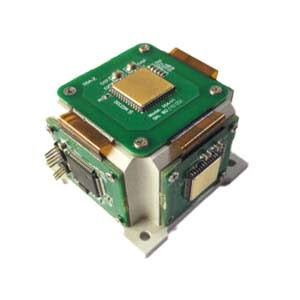

ER-MG2-022 is a high-temperature version of MEMS gyroscope developed by ERICCO. Its bias instability is <0.02°/h, angular random walk is <0.025°/√h, and the maximum operating temperature can reach 125°. This gyroscope is used in oil exploration equipment. It can not only adapt to harsh high-temperature environments, but also resist shock and vibration, prevent equipment failure or excessive wear, and reduce maintenance costs.

Follow me to get more information about MEMS gyroscope quotes and specifications.

More Technical Questions

1.Integrated method of three-axis MEMS gyroscope

2.Development history of MEMS gyroscope

3.MEMS gyroscope processing technology

4.Evolution of resonant structure of high precision MEMS gyroscope

5.Stochastic error modeling method of MEMS gyroscope

6.Signal Denoising Principle And Evaluation Index of MEMS Gyroscope

-300x300.jpg)