The 19th Ordos International Coal and Energy Industry Expo was held in Ordos today. It brought together more than 500 global energy equipment manufacturers, technology solution providers and industry experts, with an exhibition area of over 80,000 square meters.

At this industry event that brings together global wisdom, Ericsson exhibited a full range of mining north-seekers developed independently. Today I will introduce two of the north-seekers in detail:

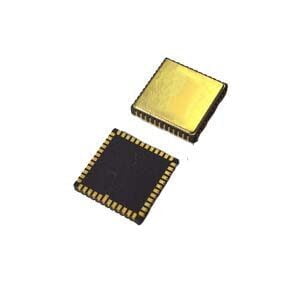

Fast MEMS North-seeker for Roadheaders (ER-MNS-04A/B)

The ER-MNS-04A/B fast MEMS north-seeker, designed for roadheader orientation, was launched, breaking the limitations of traditional orientation equipment with large size and slow alignment, and achieving three core breakthroughs: 30 seconds fast north-seeking, 0.5° north-seeking accuracy, and all-solid-state impact resistance!

1. Fast alignment capability

In response to the urgent need for fast orientation of the tunnel boring machine during tunnel excavation, ER-MNS-04A/B measures the true north direction by sensing the horizontal component of the earth's rotational angular velocity. It does not need to rely on external reference benchmarks, can accurately orient underground and is not affected by magnetic fields. It takes only 30 seconds to complete accurate north search. Users can choose 30 seconds, 60 seconds, and 90 seconds according to scene requirements.

30 seconds to achieve a fast alignment accuracy of 1° (1σ), and 90 seconds to achieve a precise alignment accuracy of 0.5° (1σ). This speed is several times faster than traditional equipment, which solves the pain point of waiting for calibration for a long time before the tunnel boring machine is started, greatly improves construction efficiency, and is especially suitable for complex tunnel projects that require frequent direction adjustment.

In addition to the azimuth, it also provides attitude data such as pitch angle and roll angle to provide a full range of reference for the attitude adjustment of the tunnel boring machine.

2. Extreme volume and flexible integration

ER-MNS-04A/B adopts the latest MEMS gyro technology, and its volume is compressed to the limit. The size with the shell is only 40×40×42mm, and the size without the shell is 27×26×34mm. It weighs less than 80g and can be easily embedded in the control system of the tunnel boring machine.

Modular design supports flexible OEM customization, is compatible with mainstream communication interfaces such as RS-422, and can be seamlessly integrated into the control system of the tunnel boring machine.

3. Anti-shock structure adapts to the harsh working environment of the tunnel boring machine

The tunnel boring machine faces strong vibration and high impact underground environment. Traditional equipment often has reduced reliability due to complex structure. ER-MNS-04A/B adopts three-axis MEMS gyroscope and three-axis MEMS accelerometer strapdown inertial measurement technology, all-solid-state design without moving parts, and embedded with the original "Chinese tripod" structure inner platform. It has strong stability and can withstand severe vibration and impact. It can still stably output north data under harsh working conditions such as dust and humidity, providing a reliable benchmark for tunneling trajectory control.

MEMS directional nipple for hole directional instrument (ER-MNS-09)

ER-MNS-09 is a MEMS directional nipple for directional drilling/hole directional instrument. It aims at the three pain points of "narrow aperture, harsh environment, and demanding accuracy" in directional drilling, and reconstructs the standard of underground orientation with MEMS inertial measurement technology.

1. Special-shaped cylindrical design: 25.4mm diameter space revolution

Different from the block structure of traditional directional equipment, ER-MNS-09 adopts the latest MEMS gyro technology, which subverts the size of traditional gyro tools. It is a special-shaped cylindrical shape with a diameter of only 25.4mm and a length of 120mm. The weight is ≤150g and can be easily embedded in small spaces such as the front probe of the drilling equipment.

This design is derived from a deep understanding of the directional drilling process of coal mines. In scenarios such as gas extraction holes and geological exploration holes, the inner diameter of the drill rod is usually limited. Traditional equipment is often difficult to install or affects the drilling trajectory due to its large size. The miniaturization breakthrough of ER-MNS-09 can be seamlessly integrated into the probe or guide head at the front end of the drilling equipment, and is compatible with mainstream drilling equipment.

2. Multi-precision gradient solution: full-scene coverage from 1° to 0.25°

Aiming at the accuracy requirements of different drilling projects, ER-MNS-09, based on MEMS technology, can provide three levels of accuracy:

30 seconds fast alignment accuracy of 1°, suitable for coal mine tunnel water exploration holes, temporary support holes and other scenes with high efficiency requirements;

90 seconds precise alignment accuracy of 0.5°, meeting the trajectory control requirements of gas extraction holes;

The industry-leading 0.25° (1σ) azimuth accuracy is designed for geological exploration holes, long-distance through-layer drilling and other scenes.

Supports 20 minutes of azimuth retention accuracy, combined with a 100Hz data update rate, to provide a basis for attitude correction during the drilling process.

3. Autonomous north-seeking technology

The high-precision MEMS gyroscope that can find north by itself is adopted, which completely gets rid of the dependence on the geomagnetic field. It can stably output the true north azimuth, pitch angle and roll angle information in strong interference environments such as underground mines, metal pipes or strong electromagnetic environments.

4. Adapt to harsh environments

The three-axis MEMS gyroscope and three-axis MEMS accelerometer strapdown inertial measurement technology are adopted, which has strong stability and high reliability. The all-solid-state design without moving parts, built-in inner platform, excellent anti-impact and vibration performance, can stably operate in a harsh temperature environment of 5℃~+55℃ (high temperature model can reach +125℃), and meet the harsh working conditions of coal mines.

Dialogue with the future of smart mines with directional technology innovation

On the stage of the Ordos Coal Exhibition, the appearance of the north-seeking instrument is not only the launch of the product, but also a milestone in the transformation of underground engineering directional technology. As the intelligent construction of coal mines enters the deep water area, directional drilling is the pre-process of gas control, geological exploration, and tunnel excavation. Its accuracy and efficiency directly affect the overall intelligent level of mines. With MEMS technology as the core, our company has built a directional solution covering underground engineering, from north finding of tunnel boring machines to drilling orientation. In the future, we will continue to deepen the field of intelligent energy equipment and provide "Chinese precision" technical support for the construction of global smart mines.

We sincerely invite you to take the time to visit the Ericsson booth at booth C325-1 in Zone C to discuss new technologies in the coal mining field with us!

Application Techniques

1.Applicable to coal mines, tunnels, and exploration! North seeker's strength revealed

2.How important is the North Seeker in the field of oil、mining and drilling?

4.Efficient mining, north seeker assists mining drilling operations

5.Accurate orientation, easy to deal with! North seeker helps work more efficiently