When pipelines are buried underground, especially when crossing rivers, roads, railways, or urban areas, it's difficult to accurately determine from the surface whether their three-dimensional position is consistent with the design or whether it has shifted over time.

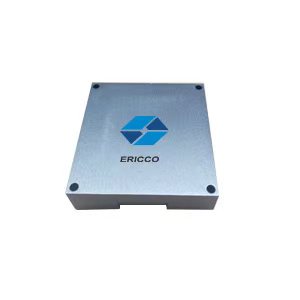

The ER-Gyro-15 gyroscopic directional module is a high-precision measurement tool designed for the following two applications, where data accuracy is paramount and the environments are most demanding:

Construction Phase: Trenchless Directional Drilling (HDD) Pipe Laying and As-Finish Surveying

The ER-Gyro-15 gyro directional module supports measurement while drilling, single-point, and continuous measurements. It can determine azimuth (1°) in as fast as 30 seconds.

During pilot hole drilling, it is installed behind the drill bit and measures and transmits azimuth (0.5°), well inclination (0.1°), and tool face angle (1°/secL) in real time.

During as-Finish Surveying, it is placed inside the newly laid pipeline and pulled or pushed throughout the entire process. The pipeline's azimuth, well inclination, and tool face angle are recorded point by point.

What can it do?

Precision Guidance: Ensures the drill bit strictly follows the designed 3D trajectory, accurately passing under obstacles (such as rivers, roads, and buildings), avoiding collisions with existing underground pipelines and cables, and accurately exiting the excavation at the intended location.

As-Built Trajectory: The ER-Gyro-15 works with other sensors to integrate data and accurately reconstruct the 3D coordinates of the entire pipeline underground, generating a highly accurate "as-built trajectory map."

Operation and Maintenance Phase: Pipeline Internal Trajectory Mapping and Inspection

The environment surrounding a pipeline may change due to geological disasters, changes in ground loads (such as construction above), and other factors, causing stress, deformation, or even displacement in the pipeline.

Integrating the ER-Gyro-15 into a pipeline inspection gauge (PIG) continuously records its 3D posture and orientation changes as the gauge is propelled by the fluid.

What can it do?

Mapping the Actual Trajectory: Obtain the actual 3D coordinates of the pipeline after installation and compare them with the design drawings.

Detecting Deformation and Settlement: Identifying pipeline bending, settlement, or displacement caused by geological changes, ground loads, and other factors.

Overcoming Measurement Challenges in Specific Environments

In-Casing Inspection: To protect main pipelines, steel casing is often installed. The confined space within the casing creates a strong magnetic shielding effect, rendering all magnetic measurement instruments ineffective.

Specific Applications: With its 25.4mm diameter and built-in gyroscope, which operates using the Earth's rotation to orient itself, the ER-Gyro-15 easily penetrates the annular space between the casing and the main pipeline and measures directly within the casing, accurately mapping the actual trajectory and position of the casing/protected pipe.

Slightly Inclined Pipelines: During the entry and exit stages of horizontal directional drilling (HDD), as well as in many urban underground pipelines, pipelines are not vertical but tilted at very small angles (nearly horizontal). This presents a blind spot for most measurement tools.

Specific Applications: The ER-Gyro-15 maintains highly accurate azimuth (<3°) and tool face angle output even in these shallow-angle conditions. It can guide horizontal drilling for precise track placement and verify whether nearly horizontal pipelines in urban areas have experienced horizontal displacement.

Application Techniques

1.MEMS Gyro Directional Module fully upgraded,Redefined measurement standards

2.How can MEMS directional module achieve precise targeting?

3.ER-Gyro-15: MEMS Directional Sensor that Redefines Downhole Exploration Accuracy

4.MEMS Gyroscope Directional Module for GWD: New solutions for well logging

5.MEMS Directional Sensor Newly Released: an Innovative Tool for Oil Drilling Technology

6.Accurate Directional Attitude Measurement Helps Revolutionize Underground Engineering!

More Products

Mems Orientation Module To Replace Fluxgate

Mems Orientation Module To Replace Fluxgate Quick MEMS North Seeker for Heading Machine

Quick MEMS North Seeker for Heading Machine Dynamic MEMS north Seeker for Heading Machine

Dynamic MEMS north Seeker for Heading Machine Low Cost MEMS North Seeker for Heading Machine

Low Cost MEMS North Seeker for Heading Machine High Accuracy Single-Axis MEMS Gyro

High Accuracy Single-Axis MEMS Gyro MEMS Gyro Directional Module for MEMS Directional Drilling/Drilling Directional Instrument

MEMS Gyro Directional Module for MEMS Directional Drilling/Drilling Directional Instrument