The miniature body carries the revolution of drilling orientation, achieving a precision miracle in a strong magnetic environment

When drilling equipment goes deep underground and traditional directional tools are inaccurate due to magnetic field interference and cannot be deployed in confined Spaces - the ER-MNS-09 provides a revolutionary answer

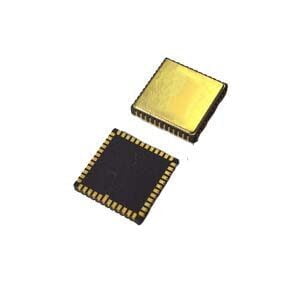

The latest MEMS gyroscope technology, ultra-small size

Adopting the latest MEMS gyroscope technology, with a 30mm×120mm ultra-fine cylindrical design, it can be easily embedded in extremely narrow Spaces such as probe tubes, breaking the size constraints of traditional gyroscopes and allowing the directional module to approach the tip of the drill bit for the first time

Three-axis MEMS direct-coupled inertial navigation technology

The three-axis MEMS gyroscope and three-axis MEMS coupled with the jet-link technology can sense the angular velocity of the Earth's rotation and the gravitational vector in real time. Through multi-dimensional data fusion and calculation, the azimuth and inclination Angle accuracy is pushed to the limit, while also achieving the attitude maintenance function

All-solid-state design, resistant to vibration and shock

The all-solid-state design and built-in inner platform have no moving parts and are not afraid of high-frequency vibration and shock. Even on the front line of high-temperature and high-pressure drilling, the precision remains as stable as a rock

Efficient alignment

30-second rapid alignment: Azimuth accuracy of 1°, speed far exceeding traditional solutions

90-second ultimate alignment: Azimuth accuracy of 0.5°, comparable to that of fiber optic gyroscopes

Self-locating high-precision MEMS gyroscope

Abandoning the magnetic reference, the self-finding north technology based on the vector induction of the Earth's rotation can ignore magnetic field interference even in iron mining areas and near high-voltage power grids

Application scenarios

Directional operation in a strong magnetic interference environment

Scene features: There is natural or artificial strong magnetic field interference in the operation area (such as in iron-bearing strata or near power facilities).

Solution: By using the self-finding north function to avoid the influence of magnetic fields, there is no need to rely on external magnetic references, ensuring the accuracy of orientation

Attitude control of downhole tools in narrow Spaces

Scene features: The internal space of the drilling tool is extremely limited (such as the measurer system while drilling, small-diameter exploration tubes)

Solution: The micro-cylinder design is directly embedded in the front end of the device, accurately outputting azimuth and inclination data in real time, and achieving attitude maintenance

Precise guidance under high vibration conditions

Scene feature: The drill bit generates continuous high-intensity mechanical vibration when breaking through the rock

Solution: The all-solid-state anti-vibration structure maintains stable operation and avoids attitude data drift caused by impact

Application Techniques

1.Applicable to coal mines, tunnels, and exploration! North seeker's strength revealed

2.How important is the North Seeker in the field of oil、mining and drilling?

4.Efficient mining, north seeker assists mining drilling operations

5.Accurate orientation, easy to deal with! North seeker helps work more efficiently