The 19th Ordos International Coal and Energy Industry Expo entered the second day, and the popularity of our booth C325-1 in Zone C continued to rise. Among the equipment focusing on coal mine automation and digital upgrades, our company's heavy-duty MEMS north finder for underground hydraulic supports in coal mines and dynamic real-time MEMS north finder for tunneling machines have become the focus with their innovative technology and practical performance, providing solutions to the problem of precise orientation in coal mining.

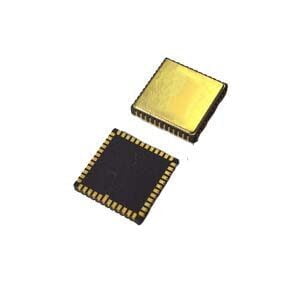

MEMS north finder for underground hydraulic supports in coal mines (ER-MNS-10A)

In coal mining, hydraulic supports are one of the most important equipment in comprehensive mechanized coal mining methods, and precise orientation is a key link in realizing intelligent mining. Traditional north-seeking equipment is limited by volume, weight, and magnetic field interference, and it is difficult to meet the needs of narrow underground space and complex geological environment. ER-MNS-10A north finder breaks through the industry bottleneck with cutting-edge technology, and its core competitiveness is reflected in three dimensions:

1. Subversive thin and light design, suitable for extreme installation scenarios

The latest MEMS gyro technology is used to compress the thickness to 14mm and the weight to 40g. The flat structure design can be easily embedded in the narrow gap of the hydraulic support system. It solves the problem of "difficult installation and large space occupation" of traditional equipment, and is especially suitable for thin coal seam mining and old equipment transformation scenarios. With an ultra-thin body, it can achieve a north-seeking measurement accuracy of 1° (1σ), and can output attitude information such as pitch angle and roll angle at the same time.

2. Self-seeking north capability and environmental adaptability, breaking through the limitations of underground operations

The high-precision MEMS gyroscope that can self-seek north is used to measure the true north direction by measuring the horizontal component of the earth's rotation angular velocity. It can accurately seek north in the underground without GPS signals, completely free from magnetic field dependence, and completely get rid of the influence of the electromagnetic environment and metal ore body on the orientation accuracy of the coal mine underground, ensuring that the hydraulic support always maintains the stability of the north reference during the dynamic frame shifting process.

The latest MEMS gyro and three-axis strapdown inertial measurement technology are adopted, which has high stability and reliability. The all-solid-state design can withstand the impact and vibration of underground operations.

The 5℃ to 55℃ wide temperature compensation technology can adapt to complex working conditions such as humidity and high temperature underground. It can output data stably within the inclination range of -85° to 85°, meeting the operation requirements of special geological conditions such as inclined coal seams and fault zones.

3. Efficient data interaction and integration capabilities enable intelligent mining

100Hz update rate + RS-422 communication interface, supports direct connection with the hydraulic support electro-hydraulic control system, realizes the closed-loop control of "seeking north - positioning - attitude adjustment", and helps coal mines realize automatic frame shifting and precise support.

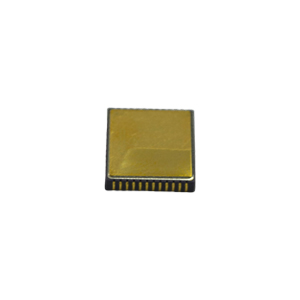

Dynamic real-time MEMS north finder for roadheaders (ER-MNS-05A)

In complex and changeable mining environments, especially in underground tunnels, deep open pits or signal shielding areas, traditional orientation methods (such as GPS and magnetic compasses) face problems such as insufficient accuracy, signal susceptibility to interference or even failure. This brings huge risks and inconveniences to key links such as accurate measurement, equipment navigation (such as drilling rigs, roadheaders, unmanned mining trucks), personnel safety, and geological guidance in mines. ER-MNS-05A can effectively solve these pain points and achieve all-weather, high-precision, and anti-interference autonomous orientation.

1. Fast and accurate: dynamic tracking measurement

ER-MNS-05A can perform dynamic tracking and holding measurements, quickly aligning the azimuth accuracy of 1° in 30 seconds, and when the alignment accuracy is 0.5°, the tracking and holding accuracy can be 0.5°/20 minutes, meeting the high-precision requirements of fast orientation of roadheaders.

2. Subverting tradition: "True North" measurement that gets rid of magnetic field dependence

In the complex electromagnetic environment of coal mines, traditional magnetic field-dependent measurement equipment often causes pointing deviations due to interference, which becomes a key pain point that restricts tunneling accuracy. The ER-MNS-05A north finder accurately measures the angular velocity component of the earth's rotation without relying on external signals (such as GPS, geomagnetism). In harsh environments such as complete shielding, strong electromagnetic interference, polar regions, and underground, it can still quickly and stably find north autonomously and maintain high-precision orientation, completely getting rid of magnetic field interference. This technology enables the equipment to always maintain a stable azimuth reference in underground tunnel operations such as coal mines and metal mines, providing reliable directional support for large equipment such as tunneling machines and continuous coal mining machines.

3. Modular design: flexibly adapt to the needs of mining equipment upgrades

ER-MNS-05A adopts the latest MEMS gyroscope technology to achieve a lightweight modular architecture, with a shell size of only 70×65×45mm and an inner platform size of 43.2×43.2×35.5mm, weight ≤100g, can be easily integrated into compact equipment such as tunneling machines and mining AGVs.

Supports OEM customized development, with sufficient internal space reserved and strong scalability. It can flexibly adapt to existing equipment upgrades or new project development, effectively reducing integration costs and shortening development cycles.

4. Environmental adaptability and reliability design

Adopting three-axis MEMS gyroscope and accelerometer strapdown inertial measurement technology, all-solid-state design, combined with the internal platform structure, it can withstand severe vibration shocks in mining operations, and the operating temperature range covers 5℃ to 55℃. It can still operate stably in harsh environments such as dust and humidity.

Intelligently lead the future of mines, a new chapter of win-win cooperation

The successful display of the 19th Ordos Coal Expo is the result of ERICCO's efforts in mining. The launch of the North Finder is not only a reflection of our technical strength, but also a practice of our commitment to promote the safe, efficient and intelligent development of the mining industry.

We firmly believe that the North Finder will become the preferred tool for mining companies, equipment manufacturers and solution providers in the field of precise positioning and navigation, and jointly open a new chapter in the construction of intelligent mines!

ERICCO sincerely invites industry partners to visit the booth (C325-1, Zone C) for in-depth exchanges, or inquire about the detailed information and cooperation opportunities of the North Finder through the official website and official hotline. Let us work together to draw a grand blueprint for smart mines with precise positioning and navigation technology!

Application Techniques

1.Applicable to coal mines, tunnels, and exploration! North seeker's strength revealed

2.How important is the North Seeker in the field of oil、mining and drilling?

4.Efficient mining, north seeker assists mining drilling operations

5.Accurate orientation, easy to deal with! North seeker helps work more efficiently