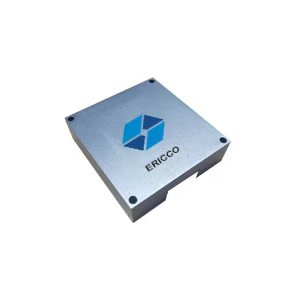

ER-3MG-064 is a three-axis MEMS gyroscope designed for industrial-grade motion sensing. Through miniaturization, low power consumption and high reliability architecture, it provides accurate angular velocity measurement solutions for multiple fields, achieving a double breakthrough in performance and practicality. Signal transmission is completed through the RS-422 digital interface, building a technical link of "miniaturized sensing - high-speed processing - accurate output".

**Miniaturization and low-power design**

The latest MEMS gyroscope technology is only 38.6mm×44.8mm×25.5mm in size and weighs ≤70g, which is significantly smaller than traditional gyroscopes and is suitable for space-constrained scenarios (such as drones, robots, robotic arms, and wearable devices).

The low-power architecture supports wide voltage input (6-12V) and can adapt to a variety of power supply environments in industrial applications, reducing the complexity of system integration.

**High-precision sensing performance**

Range and data update: 400deg/s range covers most dynamic motion scenes, and 400Hz data refresh rate ensures real-time capture of high-frequency motion signals (such as rapid steering of construction machinery).

Stability parameters: bias instability reaches 1°/hr, angle random walk <0.2°/√h, meeting the accuracy requirements of long-term posture monitoring.

Environmental adaptability: working temperature range - 45~+85℃, storage temperature - 55~+105℃, can work stably in harsh environments such as severe cold and high temperature.

**Multi-dimensional applications**

Robot navigation and balance control

The motion posture is solved through three-axis angular velocity data, and dynamic obstacle avoidance is achieved by combining visual SLAM. Such as AGV and quadruped robots.

Humanoid robots; gyroscopes are deployed at key joints such as the robot's hip joint and knee joint to monitor the angular velocity of joint rotation in real time to achieve balance control during walking. (UBTECH Walker X robot knee joint angle control)

UAV: When the drone encounters crosswind, the gyroscope quickly detects the roll/pitch angular velocity of the fuselage, and the flight control system adjusts the motor speed accordingly to offset the impact of wind disturbance.

Industrial robotic arm: The robotic arm posture is adjusted through real-time angular velocity data to improve operation accuracy.

Geotechnical and mining monitoring: Embedded in underground sensor networks to monitor rock displacement and mine collapse risks to ensure operation safety.

Application Techniques

1.Error Generation Mechanism of MEMS Gyroscope Under High Acceleration Condition

2.Bandwidth test method of MEMS gyroscope

3.Packaging of MEMS gyroscope: Structural Analysis of Deep Hole Packaging

4.Research on scale factor nonlinearity of MEMS gyroscope

5.Analysis of drive loop noise of MEMS gyroscope

6.Bias Temperature Compensation Analysis of MEMS Gyroscope