On June 26, the 19th Ordos International Coal and Energy Industry Expo came to an end. At this grand event with the theme of "Intelligent Empowerment and Green Transformation", two products of ERICCO were well received, bringing new solutions to the fields of mining and energy exploration with subversive traditional technologies.

Directional sub for drilling measurement (ER-Gyro-15)

In the underground coal mining scene, equipment using traditional magnetic sensors often suffers from inaccurate azimuth measurement due to metal interference such as casing and drill pipe or abnormal geomagnetic field, which becomes a key problem restricting operation efficiency. With gyro directional technology and the earth's rotation angular velocity sensing as the core, ER-Gyro-15 completely gets rid of magnetic field dependence and performs dynamic and continuous tracking measurement of well inclination, tool face angle and azimuth. Achieve technological breakthroughs in the following dimensions:

1. High-precision dynamic continuous tracking measurement

By integrating the data of three-axis MEMS gyroscopes and accelerometers, it supports measurement while drilling, point measurement and continuous measurement, can quickly collect drilling data and control the drilling trajectory. Real-time measurement of well inclination, tool face angle and azimuth.

30s fast alignment, azimuth accuracy can reach 1°; 90s precise alignment, azimuth accuracy can reach 0.5°. Reduce manual intervention and adapt to complex downhole environments.

The gyro tool face angle accuracy is 1°secL (L is latitude), and the well inclination alignment accuracy is 0.1° (1σ). Meet the needs of precise control of downhole trajectories.

Wide measurement range: The measurement range of azimuth and gyro tool face angle covers 0~360°, the well inclination measurement range is -180~180°, and the tilt angle measurement range is 0~90°.

It is suitable for the measurement and analysis of directional horizontal drilling trajectories in coal mine tunnels, and can also be used for the measurement of drilling inclination and azimuth of gas extraction holes, geological exploration holes, etc. in coal mines.

2. Ultra-micro design, suitable for narrow spaces

The latest MEMS gyro technology is used to subvert the size of traditional gyro tools. The diameter is only 25.4mm, the length is 120mm, and the weight is ≤150g. It is suitable for various narrow underground spaces and can be easily embedded in narrow front-end spaces such as probes or logging instrument strings to reduce dependence on borehole diameter. It is especially suitable for small-diameter directional drilling scenarios. It is suitable for narrow working environments such as coal mine drilling and tunnel excavation.

3. Strong adaptability, no worries in extreme environments

Not affected by magnetic fields: Equipped with a high-precision MEMS gyroscope with self-seeking function, there is no need to repeatedly find the reference direction. It can achieve "self-seeking" in strong interference environments such as underground mines, metal pipelines or strong electromagnetic environments. It is not interfered by magnetic materials and effectively solves the problem of borehole trajectory measurement accuracy under magnetic field interference.

All-solid-state design: no mechanical moving parts, built-in inner platform, excellent impact and vibration resistance, suitable for high-dynamic environments, and can work stably in high-frequency vibration underground.

High temperature resistant design: 5℃~+55℃ (high temperature model can reach +125℃) full temperature calibration compensation, adapt to extreme environments, and the miniaturized design can also effectively extend the use time of the thermos.

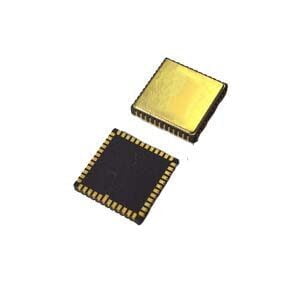

Open hole directional north finder (ER-MNS-09)

After the ER-Gyro-15 detonated the exhibition, ERICCO launched the ER-MNS-09 again according to different needs, which improved the azimuth accuracy, and can realize azimuth measurement, real-time output of the carrier's attitude reference value, and attitude holding function. With the characteristics of short north-seeking time and high north-seeking accuracy, it provides solutions for coal mine directional drilling, trenchless engineering and other fields. ER-MNS-09 is based on MEMS gyro inertial orientation technology, using "Earth rotation induction" to replace geomagnetic reference, achieving three major technological breakthroughs:

High-precision measurement capability

Adopting advanced MEMS gyro and accelerometer fusion technology, it can achieve accurate measurement of parameters such as azimuth, pitch angle, roll angle, etc.

Fast north search: The initial north search can be completed in 30 seconds, with an azimuth accuracy of 1° (suitable for emergency conditions), and the accuracy is increased to 0.5° in 90 seconds (meeting high-precision construction requirements). It is suitable for scenarios with high speed requirements such as coal mine tunnel water exploration holes and temporary support holes.

The 5-minute azimuth accuracy can reach up to 0.25° (1σ), which is comparable to fiber optic gyroscopes, meeting the needs of various projects for high-precision measurement. It is suitable for gas extraction holes, geological exploration holes, long-distance through-layer drilling and other scenarios.

The 100Hz update rate outputs azimuth, pitch angle, and roll angle in real time, and the 20-minute attitude maintenance accuracy ensures that the drilling trajectory is controllable throughout the entire process.

Compact design and environmental adaptability

Special cylindrical design: Using the latest MEMS gyro technology, with a diameter of 25.4mm, a length of 120mm, and a weight of ≤150g, it can be directly integrated into the front-end probe of the drilling equipment, and is suitable for narrow scenes such as thin coal seam mining in coal mines and urban underground pipeline micro-tunnels.

All-solid-state anti-vibration structure: Built-in inner platform design, strong anti-impact and vibration ability, stable operation in high-frequency vibration environment underground.

Wide temperature adaptability: It can operate stably in harsh temperature environments of 5℃~+55℃ (high temperature models can reach +125℃), meeting the harsh working conditions of coal mines.

Self-seeking north function, not affected by magnetic field

The true north direction is determined by measuring the rotation component of the earth, which does not rely on the geomagnetic field and can work normally in underground mines, metal pipelines, and strong electromagnetic environments. Actual measurements show that its azimuth measurement in a metal environment is not disturbed, ensuring data accuracy.

The era of precision energy exploration has arrived. On the last day of the exhibition, we sincerely invite you to visit our booth to explore technological innovation and let precise measurement help every meter!

We sincerely invite you to take the time to visit Ericsson booth C325-1 in Zone C!

Application Techniques

1.Applicable to coal mines, tunnels, and exploration! North seeker's strength revealed

2.How important is the North Seeker in the field of oil、mining and drilling?

4.Efficient mining, north seeker assists mining drilling operations

5.Accurate orientation, easy to deal with! North seeker helps work more efficiently