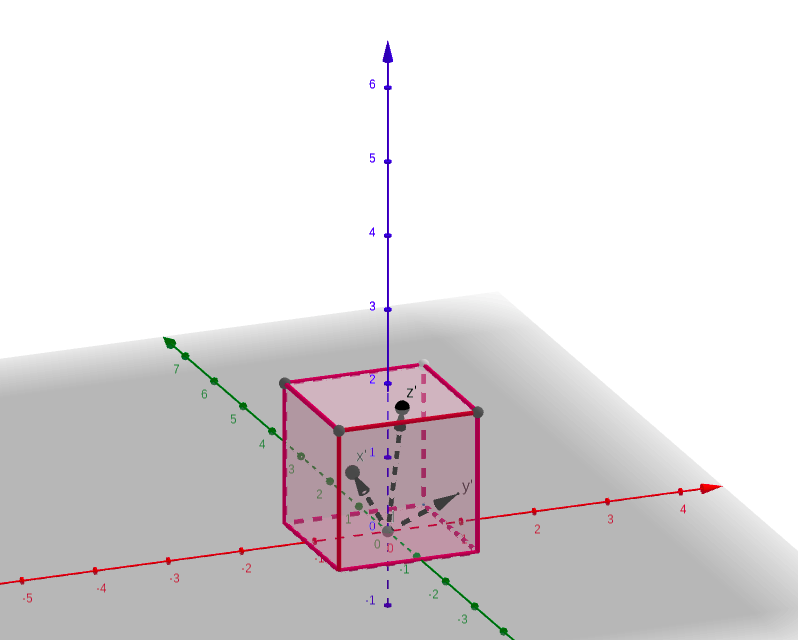

MEMS IMU, Micro Electro-Mechanical System Inertial Measurement Unit, low-precision MEMS IMU is a sensor module that integrates a micro accelerometer and a micro gyroscope. It is mainly used to measure the acceleration and angular velocity changes of objects in three axes. This kind of sensor is mainly used in fields such as attitude angle measurement, motion status monitoring, navigation and positioning. Compared with high-precision MEMS IMU, low-precision MEMS IMU has lower accuracy, but has the characteristics of small size, light weight, and low power consumption. It is suitable for application scenarios with low accuracy requirements and limited cost.

The accelerometers of low-precision MEMS IMUs are generally produced using micromachining technology and have the advantages of wide measurement range, high resolution, and good reliability. The gyroscope is implemented using vibration or optical principles, which has the advantages of fast startup speed and high measurement accuracy. In a low-precision MEMS IMU, the accelerometer and gyroscope perform data fusion and combine the initial position and velocity information to calculate the object's current position and attitude.

In practical applications, low-precision MEMS IMU needs to be used in conjunction with other sensors, such as GPS, barometer, magnetometer, etc., to improve the accuracy and stability of navigation and positioning. At the same time, low-precision MEMS IMU also requires necessary calibration and calibration to reduce the impact of various error sources and improve the accuracy and reliability of measurements.

This article will introduce the calibration process, error sources and analysis of MEMS IMU.

1.Calibration process

The calibration process of low-precision MEMS IMU mainly includes the following steps:

1.1 Static calibration

Static calibration is an important part of the low-precision MEMS IMU calibration method. Its main purpose is to eliminate the offset error of the IMU and improve its measurement accuracy in a static environment. During the static calibration process, the IMU needs to be placed in a static state, raw data in all directions is collected, and the calibration algorithm is used to estimate the parameters of the accelerometer and gyroscope. The static calibration method is relatively simple, but it is necessary to ensure the stability and temperature consistency of the IMU to reduce the impact of the external environment on the calibration results.

IMU calibration

1.2 Dynamic calibration

Dynamic calibration is another important link in the low-precision MEMS IMU calibration method. Its main purpose is to eliminate the sensitivity error and cross-coupling error of the IMU and improve its measurement accuracy in a dynamic environment. During the dynamic calibration process, dynamic excitation needs to be applied to the IMU, raw data in all directions is collected, and the parameters of the accelerometer and gyroscope are estimated using the calibration algorithm. The dynamic calibration method is relatively complex and requires the use of additional excitation equipment and precise control of factors such as frequency, amplitude, and phase of the excitation signal.

1.3 Data collection and processing

Data acquisition and processing are the basic links in the low-precision MEMS IMU calibration method. Its main task is to collect the original data of the IMU and perform necessary preprocessing and feature extraction. During the data collection process, it is necessary to ensure the accuracy and reliability of the data and avoid interference from electromagnetic interference, noise and other factors. During the data processing process, the original data needs to be filtered, smoothed, denoised, etc. to extract useful feature information to facilitate subsequent parameter estimation and model establishment.

1.4 Error model establishment

Error model establishment is the core link in the low-precision MEMS IMU calibration method. Its main task is to establish an error model based on the collected raw data and known calibration parameters to describe the measurement error of the IMU. In the process of establishing an error model, it is necessary to select appropriate mathematical models and algorithms, consider the impact of various error sources, and use a large amount of data to train and optimize the model. The established error model can be used for subsequent parameter optimization and accuracy verification.

1.5 Parameter optimization

Parameter optimization is a key link in the low-precision MEMS IMU calibration method. Its main task is to continuously optimize the calibration parameters through iteration and reduce the measurement error of the IMU. During the parameter optimization process, it is necessary to select an appropriate optimization algorithm and objective function, and use an error model to guide the optimization process. Optimized parameters usually include accelerometer and gyroscope bias, sensitivity, cross-coupling and other parameters. Through parameter optimization, the measurement accuracy and stability of the IMU can be improved to better meet the needs of practical applications.

1.6 Accuracy Verification

Accuracy verification is a necessary part of the low-precision MEMS IMU calibration method. Its main task is to evaluate the measurement accuracy of the calibrated IMU by comparing actual measurement data with known standard data. During the accuracy verification process, it is necessary to select representative test samples and use the error model to predict and evaluate the test samples. At the same time, the test results need to be compared with the uncalibrated IMU to verify the effectiveness and superiority of the calibration method. The results of accuracy verification can be used as an important basis for evaluating the performance of the calibration method.

1.7 Repeatability Test

Repeatability testing is an important part of the low-precision MEMS IMU calibration method. Its main task is to evaluate the stability and reliability of the IMU performance by conducting repeatability tests at different times and in different environments. During the repeatability test process, it is necessary to maintain the consistency of the test conditions and perform statistical analysis on the test results. By comparing the differences and trends between different test results, the performance and reliability of the IMU under different conditions can be evaluated. At the same time, the results of the repeatability test can also be used as an important basis for evaluating the performance of the calibration method.

2.Error sources and analysis

MEMS IMU errors are of great significance to improving its measurement accuracy and stability. The errors of low-precision MEMS IMU mainly come from bias error, sensitivity error, cross-coupling error, temperature error and repeatability error. The error analysis is as follows

1.Offset error:During long-term use, the accelerometer and gyroscope of MEMS IMU will have offset errors due to factors such as manufacturing processes and materials. Offset errors can cause the IMU to produce measurement errors in its stationary state. In order to reduce the offset error, long-term static calibration is required and the output of the accelerometer and gyroscope are filtered.

2.Sensitivity error:The sensitivity of the MEMS IMU's accelerometer and gyroscope will be affected by factors such as manufacturing processes and materials, resulting in errors. Sensitivity errors can lead to inaccurate IMU measurements in dynamic environments. In order to reduce the sensitivity error, dynamic calibration is required and the output of the accelerometer and gyroscope are corrected.

3.Cross-coupling error: Cross-coupling error will occur between the accelerometer and gyroscope of the MEMS IMU, especially during high-speed rotation or vibration. Cross-coupling errors can lead to inaccurate IMU measurements in dynamic environments. In order to reduce cross-coupling errors, the physical design and circuit parameters of the IMU need to be optimized, and the outputs of the accelerometer and gyroscope need to be coupled and compensated.

4.Temperature error: The performance of MEMS IMU is greatly affected by temperature, and temperature drift will cause the measurement accuracy of the IMU to decrease. In order to reduce the temperature error, temperature compensation is required and devices with lower temperature drift are selected. At the same time, materials with good thermal stability can be used in the IMU package to reduce the impact of temperature on the performance of the IMU.

5.Repeatability error:The repeatability error of MEMS IMU refers to the error caused when the same parameter is measured multiple times under the same conditions. Repeatability errors are mainly affected by factors such as manufacturing processes and materials, and can be reduced by improving manufacturing processes and material quality. At the same time, filtering algorithms and statistical methods can be used to smooth the output of the IMU to reduce the impact of random noise and accidental errors.

In short, MEMS IMU error analysis is an important means to improve its measurement accuracy and stability. By analyzing and controlling various error sources, the errors of MEMS IMU can be effectively reduced and its performance improved.

Summarize

The above article describes the calibration method, error sources and error analysis of low-precision MEMS IMU. The output of MEMS IMU will also have deviations, and the calibration coefficients will also have deviations. Therefore, it is necessary to accurately calibrate the error coefficient of the MEMS IMU to improve the calibration accuracy.

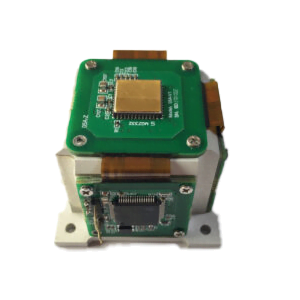

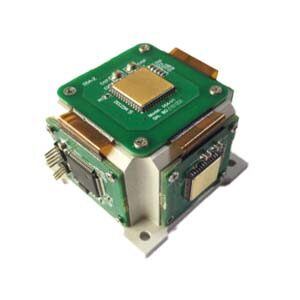

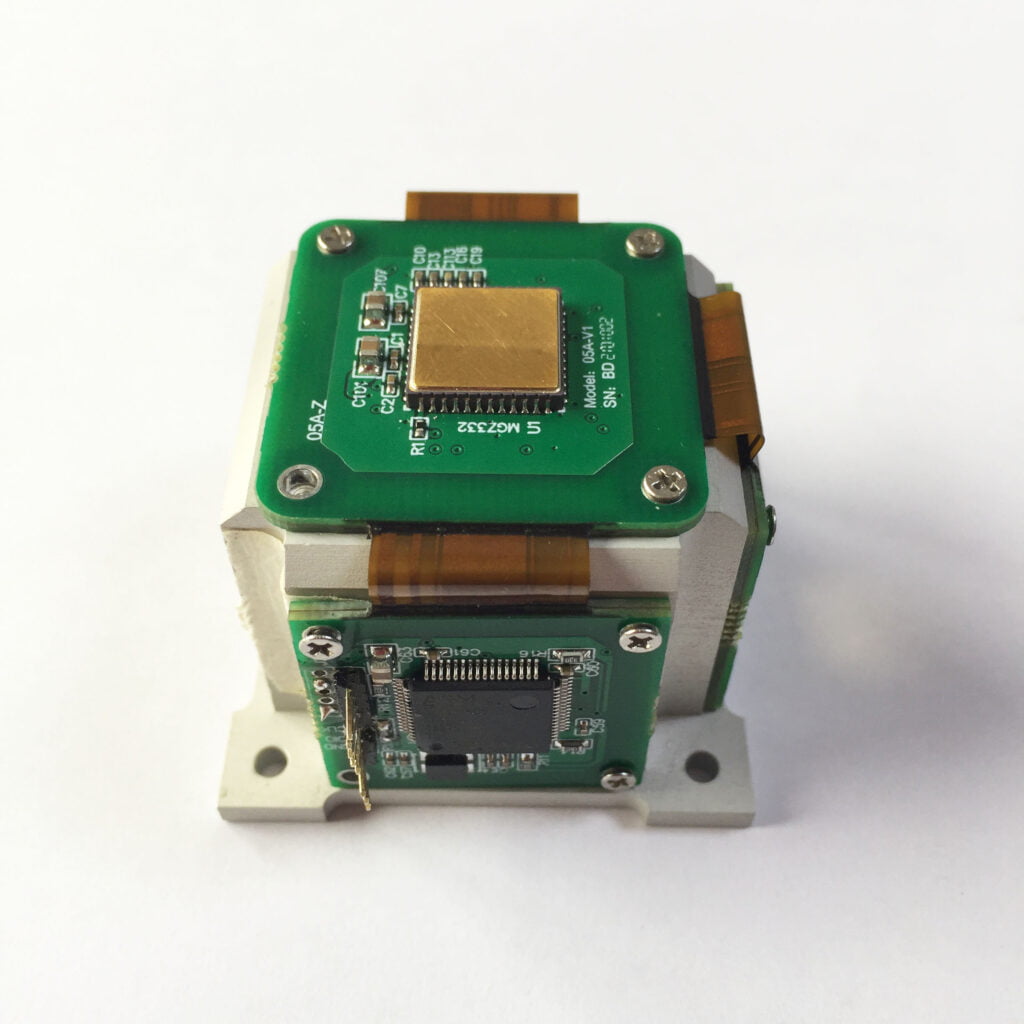

As a developer and manufacturer of MEMS IMUs, Ericco has adopted strict control measures for the calibration methods of MEMS IMUs, especially the navigation grade ER-MIMU-01 and ER-MIMU-02 with excellent accuracy and high calibration accuracy. Among them, the gyro accuracy is relatively high, and the bias instability can reach 0.01-0.02°/hr and 0.03-0.05°/hr respectively.

If you are interested in other knowledge about MEMSIMU, please click the link below to learn more.

More Technical Questions

1.MEMS-IMU error calibration compensation method that does not rely on precision turntable

2.Application of Improved Wavelet De-noising Method in MEMS-IMU Signals

3.Research on error modulation technology of MEMS based on IMU rotation

4.Research on MEMS-IMU signal denoising technology

6.IMU self-calibration based on factorization

Products in Article