In complex underground operation scenarios, the accuracy of direction and the reliability of equipment are directly related to engineering efficiency and safety. Traditional north-seeking equipment relies on fiber optic gyroscopes or mechanical structures, which have pain points such as large size, high cost, and susceptibility to magnetic field interference.

The ER-MNS-04 MEMS north finder, with its revolutionary micro-electromechanical system technology, redefines the possibility of high-precision north-seeking equipment and provides a better solution for underground engineering, geological exploration and precision equipment.

Solving industry pain points: all-solid-state design and environmental adaptability

In scenarios such as mining and tunnel construction, equipment often faces the test of severe vibration, extreme temperature differences and complex electromagnetic environments. ER-MNS-04 breaks through traditional limitations through three core technologies:

1. All-solid-state shock-resistant architecture: The mini inner platform (27×26×34mm) designed by China Ding is built in, and the seismic level reaches industrial standards, which can withstand the impact loads commonly seen in underground operations;

2. Stable output over a wide temperature range: Within the range of -5°C to 55°C, it ensures that the tunnel boring machine can continue to output reliable data in high-temperature rock formations or low-temperature water-rich formations;

3. Magnetic field immunity: The strapdown inertial measurement solution based on the three-axis MEMS gyroscope and accelerometer breaks away from the traditional dependence on the geomagnetic field and achieves accurate true north orientation in iron ore tunnels or electromagnetic interference environments.

Miniaturization and modularization to reconstruct the equipment ecosystem

ER-MNS-04 compresses the volume through structural innovation:

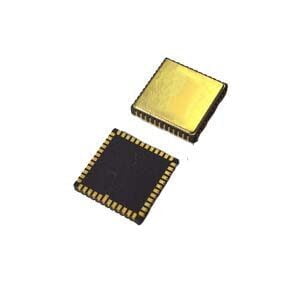

The shell is only 40×40×42mm, weighs less than 200g, and can be embedded in the guidance system of a tunnel boring machine or a drilling machine;

It supports the removal of the bottom plate shell, and the bare inner platform can be directly integrated into the customer's equipment;

The plug-and-play interface design breaks through the limitation of the dedicated 15-pin plug, and directly connects to the main control system through a standard data cable, shortening the integration time, which is particularly suitable for the rapid deployment and emergency rescue scenarios of tunnel boring machines.

Summary

ER-MNS-04 MEMS north finder is not only a technological iteration, but also the cornerstone of the intelligent transformation of underground engineering. It replaces the traditional bulky mechanical structure with MEMS chips, breaks through the physical boundaries with algorithms, and reshapes the spatial perception ability in a small space. With the advancement of the new infrastructure and deep ground strategy, this innovative equipment that integrates the design genes of China Ding is becoming an indispensable direction reference source in the era of intelligent construction. Choosing ER-MNS-04 means choosing to penetrate the stratum with technological innovation and open up infinite possibilities of underground space with precise orientation.

Application Techniques

1.Applicable to coal mines, tunnels, and exploration! North seeker's strength revealed

2.How important is the North Seeker in the field of oil、mining and drilling?

4.Efficient mining, north seeker assists mining drilling operations

5.Accurate orientation, easy to deal with! North seeker helps work more efficiently