Quartz accelerometer is widely used in the field of high precision inertial navigation for its advantages of high precision, small size and good stability. The existing digital servo circuit technology scheme adopts the way of separating the meter head from the servo circuit, and the capacitor signal is easily interfered with in long-distance transmission. Therefore, high precision and high integrated digital output is the inevitable trend of the development of quartz flexible acceleration sensors.

Digital closed loop system

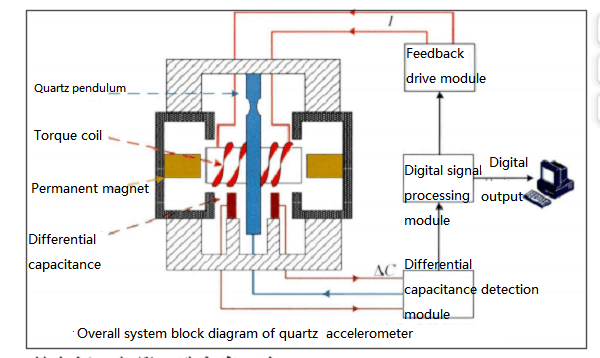

The whole digital closed-loop system mainly includes four parts: meter head assembly, differential capacitance detection module, digital controller module and feedback drive module, as shown in the figure. The basic principle is as follows: as the middle plate of the differential capacitor, the quartz pendulum plate generates a small displacement when it is stimulated by external acceleration, which changes the gap with the plates on both sides, so as to output the changed capacitance. The capacitance detection module converts the capacitance signal carrying acceleration information into a digital quantity and transmits it to the digital controller module. The digital controller module is the control core of the closed-loop system, and the field programmable logic array can realize the complex control algorithm to get the appropriate feedback control amount, and the drive circuit will apply the feedback current to the torquer, forcing the pendulum to return to the balance position, and finally realize the closed-loop control of the acceleration sensor. In addition, the digital acceleration information can be directly output to the navigation computer to avoid additional quantization errors.

Quartz accelerometer digital servo circuit as a whole presents a mixed structure, the analog part of the differential capacitance detection module and feedback drive module should pay attention to noise suppression, the digital part of the controller design should pay attention to stability and dynamic characteristics of the improvement.

Accelerometer closed-loop system model

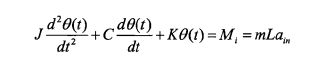

According to the working principle of quartz accelerometer digital servo system, the transfer function of each link can be analyzed, and the closed-loop system model can be established. The quartz pendulum plate is sensitive to the external accelerometer input through the flexible support beam and deflections. The external input acceleration a in has the following relationship with the deflection Angle displacement θ :

J-- the moment of inertia of the inertial mass;

C-- damping coefficient;

K-- the elastic coefficient of quartz spring sheet;

Mi- acceleration moment;

M-- pendulum quality;

L-- the distance from the center of gravity of the pendulum to the flexible support beam.

Digital control

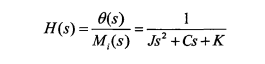

The design of digital controller depends on the accurate closed-loop system model. Only by knowing the specific mathematical expression of the model, can we design the appropriate controller parameters according to the characteristics of the table head and compensate the table head model. In the closed-loop system of the accelerometer, the other links except the mechanical dial head and the digital controller are all proportional links and do not affect the system order, so the accuracy of the dial head model is very important for the design of the digital controller. The quartz pendulum transfer function is shown in the equation.

If you can obtain the pendulum material, size and other information can be calculated to get the transfer function H(s), but some table manufacturers do not provide these parameters, even if you can obtain these parameters, the real parameters of each table head due to the production and installation error of the component will be different from the theoretical value.

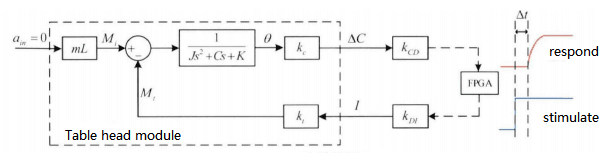

Since the structure and order of the model have been determined, the pendulum transfer function can be obtained by open-loop model identification. During the experiment, under the condition that there is no input acceleration from the outside and the quartz pendulum is in a state of natural ptosis, the digital controller is disconnected, and the excitation signal is output through FPGA to drive the torquer. The response curve is obtained after the drive module, the watch head component and the acquisition module. The block diagram of the system open-loop model identification is shown in the figure.

Summary

In this paper, the digital closed-loop system of quartz accelerometer is briefly introduced in order to understand the process of digital information processing more clearly, and with the continuous optimization of the system design, the data information will be calculated more accurately. Ericco's ER-QA-03A also uses digital output to improve accuracy and meet the needs of inertial systems. If you are interested in other quartz accelerometer related topics, please click on the related articles and products below.

More Technical Questions

1.Calibration Method of Accelerometer

2.How to Improve the Long-term Stability of the Quartz Accelerometer?

3.What is the Effect of Temperature Coefficient on Quartz Accelerometer?

4.What are the Advantages and Disadvantages of Quartz Accelerometers?

5.What is Sensitivity and Measurement Range in Quartz Accelerometer?

6.Quartz Accelerometer VS MEMS Accelerometer

Products in Article