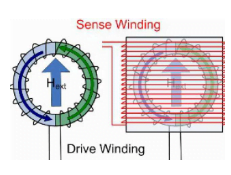

Fluxgate directional assembly is an important component used in MWD, and fluxgate sensor is its core element. Fluxgate sensors are typically toroidal magnetic cores made of highly permeable alloys with two coil windings wrapped around them: the drive winding and the induction winding (as shown in Figure 1). If the sensor is to operate in a closed loop, some sensors will also have a third feedback winding.

Figure 1 The structure of fluxgate sensor

Think of the ring core as two separate semi-cores as shown in blue and green in the figure. The ring core is used to measure the Hext direction of the magnetic field. When a current flows through the drive winding, one half of the core will generate a magnetic field with a component in the same direction as the Hext, and the other half will generate a magnetic field with a component in the opposite direction of the Hext.

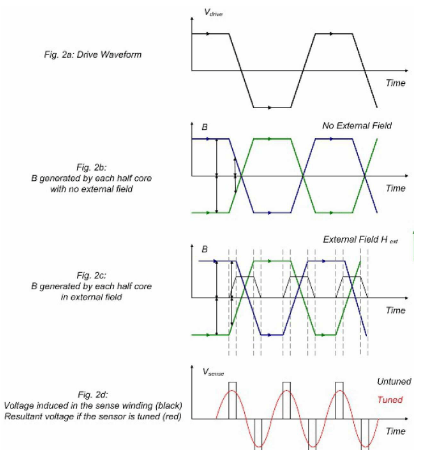

Driver waveform: Figure 2a shows an example driver waveform. In fact, transitions are more "square" than shown in the figure, where they are exaggerated to emphasize what happens in the 2 half-cores.

No outfield: In the absence of an outfield (Hext= 0), two half cores enter and exit the saturated state simultaneously. The resulting magnetic field completely cancels out, as shown in Figure 2b, and there is no net change in the magnetic flux in the detection winding, so there is no induced voltage.

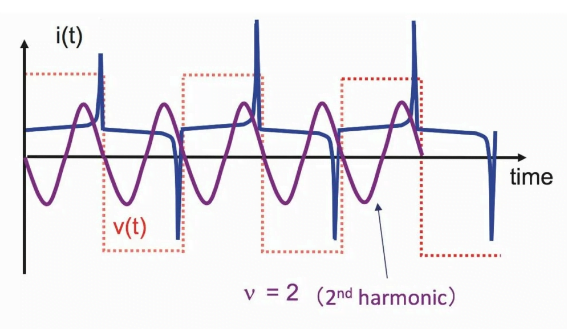

External magnetic field: When there is an external field, the half core that produces a field in the opposite direction of the external field (the first transition in Figure 2c, shown in green) is faster out of saturation, and the half core that appears in the same direction as the external field is out of saturation. During this time, the magnetic field does not cancel out and there is a net change in the magnetic flux in the detection winding (shown in black). According to Faraday's law, a net change in magnetic flux produces a voltage, as shown in black in Figure 2d. Similarly, at the end of the transition, the half-core now generates a magnetic field in the same direction as the Hext, entering the saturated state faster. As a result, there are two voltage spikes for each transition in the driver, and the induced voltage is twice the drive frequency.

Measurement field: The size and phase of the inductive spikes tell us the size and direction of the external field. To help amplify this signal to make it easier to detect, fluxgate magnetometers produced at Imperial College use capacitors to adjust the induction windings. The tuned sensor waveform is shown in red in Figure 2d.

Figure 2 The magnetic field of fluxgate

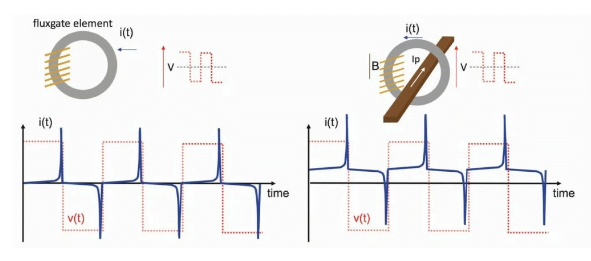

Figure 3 illustrates the basic fluxgate technique, showing the effect of applying a square-wave voltage (left), resulting in sharp positive and negative signals, and then if the primary DC current Ip through the wire is introduced, a DC magnetic field is added, thus diverting the signal (correctly). Finally, advanced signal processing is applied, and by using second harmonics, the value of the new signal can be extracted to provide a measurement of the current in the conductor and its DC current value. This can be supplemented by additional AC feedback windings to extend the frequency range of AC current measurements.

Figure 3 Fluxgate technology schematic diagram

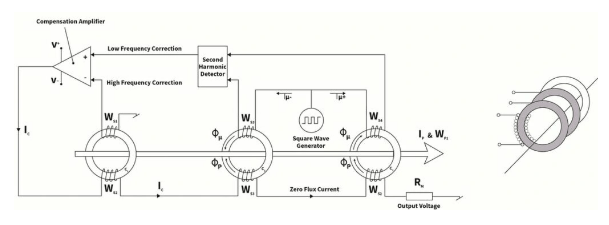

The fluxgate structure uses two opposite magnetic cores, similar in concept to a Wheatstone bridge. This provides natural compensation and eliminates the effects of any drift. The block diagram is shown in Figure 4, and the signal simplification diagram is shown in Figure 5. However, in order for the two fluxgate elements to balance each other, they must be perfectly matched.

Figure 4 Fluxgate structure block diagram

Figure 5 Simplified fluxgate signal diagram

Fluxgate directional assembly is mainly based on the working principle and technology of fluxgate, it can play a role in the field of oil logging and directional drilling, applied to MWD and logging tools, so that operators can grasp the downhole work in real time, so as to better complete the work. The categories of fluxgate directional assembly can be divided into dynamic and static according to the mode of operation, and can be divided into wired and wireless according to the product structure. For example, the dynamic fluxgate directional assembly of ER-DOS-03 is shock resistant, vibration resistant, and can operate in high temperature and harsh environments. While ER-OS-07H and ER-WOS-08 are both static measurement fluxgate directional assembly, the difference between them is that ER-OS-07H is wireless and ER-WOS-08 is limited. The ER-OS-07H can withstand higher operating temperatures and can operate at a high temperature of 175 degrees.

If you want to know more about fluxgate directional assembly, please contact us.

More Technical Questions

1.How Do Fluxgate Directional Assembly work in MWD

2.GWD - Gyro-while-drilling Technology Superior to Traditional MWD

3.Three Signal Transmission Methods of MWD Inclinometer While Drilling

4.What Is The Difference Between MWD And LWD?

5.What Is The Principle Of MWD?

6.Borehole north finding: Shock vibration compensation for MEMS gyroscope

Products in Article

.jpg)