The use of gyro-theodolite orientation for shaft joint surveying has significant advantages. Not only does it not require occupying the shaft, but it also has high orientation accuracy, which can fully meet engineering accuracy requirements. Gyro-theodolite orientation can usually measure the geodetic azimuth angle and true meridian position of the survey line at all survey stations underground or on the surface, and the orientation accuracy is not limited by the depth of the wellbore, which can improve the accuracy of the wire end point.

1.Orientation principle of gyro-theodolite in shaft contact measurement

In recent years, with the advancement of modern science and technology and the development of surveying and mapping instruments, gyro-theodolite combines gyroscopes and theodolite. Its application in actual observation and mapping is less limited by natural environment and time factors, and the observation operation is simple. , the orientation accuracy is higher. For deep well orientation, gyro theodolite can replace the previous geometric orientation method, avoiding the problem of long-term occupation of the wellbore during the orientation process, reducing the consumption of manpower, material resources and materials, while saving measurement time and improving measurement accuracy.

1.1 Orientation methods and procedures

(1) Orientation method

A large diversion tunnel has a total length of 283km, with multiple branch tunnels and shafts arranged along it. KS9 is marked as a vertical shaft plus a flat tunnel. The shaft is located at the tunnel pile number K248+800. The wellhead elevation is 1229m, the well depth is 686m, and the net diameter is 7.2m. The main tunnel pile No. K245+153~K253+193. When measuring and orienting the flat hole after the shaft excavation is completed, due to objective conditions, it is difficult to guarantee the measurement accuracy using traditional geometric orientation methods. To ensure measurement accuracy, a gyroscope is used for directional measurement during construction. During the measurement, in accordance with the relevant provisions of the "Coal Mine Surveying Regulations", a Japanese Sokia gyro total station was used (one-time orientation accuracy is 15~)

(2) Orientation program

Use the tracking inverse point method to track 5 reversal points, and calculate the swing median of the 5 reversal points according to the Schuler average method. Orientation program.

Use an orientation program. That is, before going down the well, measure the gyro azimuth angle three times on the known side of the ground, and after going down the well, measure the instrument constants two times on the known side where the original measuring instrument constants were measured. The known side of the measured instrument constant is the ground "XS34-XS32" GPS side, and the orientation side is the "S1-S2" side.

(3) Gyro orientation calculation

① Calculation of gyro azimuth angle and zero position correction. The calculation method of the azimuth angle of the reverse point method gyro is as follows:

②Calculation of instrument constants:

![]()

③Calculation of meridian convergence angle:

![]()

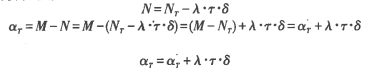

④ Calculation of the coordinate azimuth angle of the directional edge:

![]()

2.Contact Measurement

2.1 Ground connection measurement

Ground plane joint measurement plan: use XS34 as the starting point, XS34-XS32 side azimuth as the starting azimuth angle, and directly measure the steel wire. Use a total station to measure with 1" wire accuracy. The distance from the near well to the steel wire is measured with a steel ruler and inspected with a total station. The ground coordinates are guided downhole through the steel wire casting point.

Joint elevation measurement plan: Based on KS97 and KS98, joint measurement is conducted according to the second-class level measurement requirements.

2.2 throwing points

A single stable throwing point is adopted, and a high-strength carbon spring steel wire with a diameter (p2mm) is used as the steel wire for the throwing point, and a 30kg heavy weight is suspended.

2.3 Import elevation

When importing the elevation, use the elevation datum point jointly measured at the wellhead and use the steel ruler method to import the elevation. The steel ruler is placed underground through the manhole cover. After reaching the bottom of the well, a scale is hung and the steel ruler is lowered. Levels are read on the ground and underground. Finally, the steel ruler is corrected for length, temperature, tension, and self-weight of the steel ruler, and finally the bottom of the well is calculated. elevation.

3.Factors affecting orientation accuracy

In gyro-theodolite, the pendulum orientation accuracy is generally determined by the error in primary orientation. Normally, the error in primary orientation is determined when the gyro-theodolite leaves the factory and is within the specified range. However, due to certain differences in the quality of measuring instruments, the orientation accuracy is easily affected by a variety of factors, including errors during the manufacturing process. Process conditions, vibration after leaving the factory, natural conditions, etc. The gyro orientation error is related to the observation method and the gyro-theodolite orientation error. If directional measurement is performed by tracking the reversal point, a survey line is measured according to the following procedure: First, the instrument constant is measured on a known azimuth angle baseline, and centering errors easily affect the orientation accuracy. Second, the direction value of the survey line is measured on the side to be oriented. The error in the mean value of the side line easily affects the orientation accuracy. Third, the meridian direction value is measured through five swing reversal points. The errors in the determination of the north direction at these five reversal points easily affect the orientation accuracy.

Summarize

In the process of my country's economic development, for large-scale connection projects, errors should be predicted based on engineering tolerance requirements, and connection should be carried out through advanced and reasonable measurement methods and plans. At the same time, during the measurement work, the measurement procedures should be strictly implemented so that the expected penetration effect can be achieved. In the measurement of tunnel penetrations, gyro-theodolite is a commonly used instrument and plays an important role in ensuring measurement accuracy. Features of domestic ERICCO company's gyro-theodolite ER-GT-02:

- Orientation accuracy ≤3.6" (1σ);

- Strong pit interference capability, integrated body design, compact structure and stable performance;

- It has the functions of low position locking, automatic zero adjustment and observation.

If you want to know or purchase please contact us.

More Technical Questions

2.Do You Know the Application of Gyro Theodolite ?

3.What Instrument Is A Gyro Theodolite?

4.What Is The Principle Of A Gyro Theodolite?

5.What is the Structure of a Gyro Theodolite?

6.How To Orient The Gyro Theodolite?

Products in Article