Global Navigation Satellite Systems (GNSS) and GNSS augmentation technology have emerged as indispensable tools, providing precise positioning data that is fundamental for effective mine planning, safety management, and asset tracking. This article will delve into the applications of GNSS augmentation technology in mine surveying, exploring GNSS augmentation technology to showcase their real-world impact.

1. Background

The introduction of GNSS technology to the civilian community in 1980 revolutionized the surveying industry, facilitated the delivery of highly accurate and reliable positioning information in shorter periods of time, providing significant economic and social benefits.

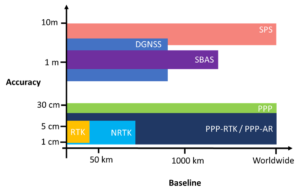

The first GNSS positioning solution used in surveying applications is stand-alone positioning using a single GNSS receiver. This receiver tracks four or more satellites to determine its coordinates with respect to a reference frame. Although this positioning technology has been employed in different surveying applications, its accuracy is limited (within a few meters) and cannot satisfy the needs of the majority of surveying applications. In order to achieve the required accuracy for these applications (within a few centimeters and a few millimeter), GNSS augmentation technologies are employed. These techniques include SBAS, DGNSS, PPP, and RTK, which aim to improve the accuracy, reliability, availability, and integrity of GNSS signals.

Among these approaches, RTK and PPP provide better accuracies compared to DGNSS and stand-alone GNSS positioning – when introducing the corrections from augmentation systems such as SBAS – as required in the majority of surveying applications. The choice between PPP and RTK is then made based on the required level of accuracy, time constraints, and availability of specific equipment in different surveying applications:

- RTK is the best choice when the intended application requires the best possible accuracy.

- Where time is a concern, RTK can achieve centimeter-level accuracy considerably faster than PPP.

- The achieved accuracy from RTK positioning is highly dependent on the distance to the base receiver. If the RTK baseline is extended, both accuracy and initialization time are ceded.

- RTK is more expensive and more complex to set up.

2. Applications of GNSS Augmentation Technology

The mining industry is mainly concerned with the exploration and extraction of solid minerals such as coals and ores, liquids such as crude petroleum, or gases such as natural gas. Hence, accurate surveying of mine sites and precise positioning of mine facilities and machines is required to ensure that efficient mining procedures can be carried out while considering environmental and safety standards.

For most mining applications, the sector requires accuracies ranging from 10 cm for monitoring and mineral tracking to 1 cm for site surveying and autonomous operation of mine machinery. The required positioning information with predefined accuracy levels was traditionally provided using terrestrial surveying techniques. However, with the public adoption of GNSS systems, the required level of positioning accuracy can be delivered more efficiently and reliably using GNSS augmentation techniques .

Exploration and mine site surveying are two major components of mining projects which are highly dependent on the availability of precise positioning information.

2.1 Exploration Precision: with DGNSS and RTK

For exploration application, decimeter-level positioning accuracy is typically required, which can be supplied by DGNSS techniques using corrections relayed by satellites or RTK with corrections delivered from localized base stations. Although DGNSS is the preferred technique for exploration activities, RTK systems are more reliable and trusted in some critical applications (e.g. pipeline construction or shore crossing) due to increased accuracy requirements. The benefits of employing GNSS positioning systems in exploration activities can be summarized as follows:

- Reduced time frames, operating cost, and improved efficiency for data acquisition

- Improvement in the reliability and certainty of positional accuracy, thus improving the efficiency of the exploration procedure

- Reduction in positional uncertainty for the delivered data

2.2 Site Surveying Precision: with RTK GNSS

Precise positioning is also a key requirement in mine site surveying applications, including pipeline location, pit layout, underground, and construction operations. The required accuracy for these applications is at the centimeter level to coordinate survey controls, perform topographical and feature surveying for design, set out design and boundaries, and survey cleared areas. This accuracy level can be reliably and timely achieved using RTK GNSS systems with corrections provided by one or more local base stations or the GBAS network. Advanced modules like the ER-GNSS-M02, equipped with RTK technology, effortlessly achieve centimeter-level positioning.

In a large-scale pipeline construction project, the integration of RTK GNSS significantly streamlined the surveying process. The accuracy achieved facilitated precise placement of pipeline segments, minimizing the environmental impact and optimizing construction timelines. The benefits of using GNSS systems in mine site surveying applications include the following:

- Efficiency in site survey updates (construction, utilities‚ and services) and reduced operation costs

- Reduced on-site surveyors required for data capture as site is developed

- Interoperability between survey and construction

- Real-time material tracking and stockpile management

2.3 Automation Advancements: GNSS Systems and Autonomous Mining Equipment

In addition to the aforementioned components, GNSS systems – augmented by other inertial sensors – can provide highly accurate real-time positioning information required for the development of remotely operated and autonomous mining equipment, thus automating mining activities. The automation of such procedures reduces costs, increases operational efficiency, and improves health, safety, and environmental performance.

One exemplary application is the integration of RTK GNSS in autonomous haulage trucks. Mining giants like Rio Tinto have deployed autonomous haulage systems featuring RTK-enabled GNSS for centimeter-level accuracy in positioning. RTK technology ensures that these colossal trucks can navigate intricate mining terrains with unprecedented precision, optimizing material transport and enhancing overall operational efficiency.

3. Conclusion

The integration of GNSS augmentation technology with autonomous mining equipment marks a pivotal milestone in the evolution of precision mapping within the mining industry. GNSS augmentation technologies such as RTK and PPP have become essential, providing unparalleled accuracy, reliability, and efficiency in mine planning, safety management, and asset tracking. As we reflect on the journey from stand-alone GNSS positioning to the sophisticated augmentation techniques of today, it becomes evident that the synergy between GNSS systems and autonomous mining equipment is reshaping the very fabric of mining operations.

Looking ahead, the trajectory of GNSS technology in mining promises continued innovation. As advancements in artificial intelligence and machine learning converge with GNSS capabilities, the industry is poised for further optimization. The successes outlined in this exploration of GNSS augmentation technology and autonomous mining equipment exemplify a paradigm shift in how mining professionals navigate and execute their operations, reinforcing the indispensability of these technologies in the pursuit of precision and efficiency in the mining sector.

I will appreciate it if you find this article helps you a lot. For more information about GNSS products, you may read the articles and products below. Always feel free to contact us:

Email: info@ericcointernational.com

More Technical Questions

1. Application of GNSS-RTK Positioning Technology in ICV Testing

2. Integration of GNSS Modules in Aviation: Precision Navigation for Unmanned Aerial Vehicles (UAVs)

3. Decoding Navigation Technology: GNSS Boards vs. GNSS Modules – Unveiling the Distinctions

4. Distinctions Between GNSS Receivers and Antennas

5. Scientific Farming, With The Help of GNSS

6. The Working Principle of GNSS

Products in Article