1.Introduction and importance of IMU

IMU (Inertial Measurement Unit) is an inertial measurement unit, which is a device used to measure the angular velocity and acceleration of objects in three-dimensional space. The IMU consists of three gyroscopes and three accelerometers, which are used to measure the angular velocity and acceleration of an object on three orthogonal axes. Because IMU can provide continuous attitude and position information, it is widely used in many fields, such as navigation, drones, robots, augmented reality, etc.

Accurate calibration of the IMU is of great significance for improving the navigation and positioning accuracy of the system. The calibration process can help us understand the error characteristics of the IMU, and then compensate for it through algorithms to improve measurement accuracy.

2.Calibration methods and classification

The calibration methods of IMU are mainly divided into two categories: static calibration and dynamic calibration. Static calibration is mainly used to evaluate the zero bias and scale factor error of the IMU, while dynamic calibration is mainly used to evaluate the nonlinear error and coupling error of the IMU.

3.Static calibration method

The static calibration method is usually carried out in a static state. By collecting the static data of the IMU in different directions, its zero bias and scale factor error are calculated. This method is simple and easy to implement, but it cannot evaluate the nonlinear error and coupling error of the IMU.

The main steps of the static calibration method:

3.1 Zero offset calibration

3.1.1 Place the IMU on a horizontal platform and keep it stationary to ensure that the IMU is free from external forces.

3.1.2 Record accelerometer and gyroscope output data for a period of time. For three-axis accelerometers and three-axis gyroscopes, the output data on each axis needs to be recorded separately.

3.1.3 For the accelerometer and gyroscope data on each axis, calculate the average. This average value is the zero offset parameter on this axis. The zero offset parameter reflects the output offset of the IMU without external force.

3.2 Scaling factor calibration

3.2.1 Place the IMU in a reference system with known acceleration and angular velocity. This reference system can provide accurate acceleration and angular velocity data for comparison with the IMU output data.

3.2.2 Record the output data of the IMU and reference system. These data should include values for acceleration and angular velocity.

3.2.3 Calculate the scale factor parameters based on the known acceleration and angular velocity and the output data of the IMU. The scale factor parameter reflects the proportional relationship between the IMU output value and the actual value.

4.Dynamic calibration method

The dynamic calibration method needs to be carried out in a dynamic environment. By collecting the data of the IMU in a moving state, its nonlinear error and coupling error can be evaluated. This method can more comprehensively evaluate the error characteristics of the IMU, but the operation is relatively complex.

5.Calibration data processing

Calibration data processing is an important part of the calibration process, which mainly includes data preprocessing, error model establishment, parameter estimation and other steps. Data preprocessing mainly involves filtering and smoothing the original data to reduce the impact of noise. The establishment of the error model is based on the error characteristics of the IMU and selecting an appropriate error model to describe its error behavior. Parameter estimation uses optimization algorithms to solve the parameters in the error model.

6.Evaluation of calibration results

The evaluation of calibration results mainly evaluates the calibration effect by comparing the data before and after calibration. Evaluation indicators usually include the root mean square value of error, maximum error, minimum error, etc. If the error after calibration is significantly reduced, it means the calibration is effective.

7.Precautions and Tips

When performing IMU calibration, you need to pay attention to the following points:

- Ensure the calibration environment is stable and avoid external interference.

- Choose an appropriate calibration method and select an appropriate error model according to actual needs.

- During the calibration process, keep the IMU in a fixed posture to prevent it from moving or rotating.

- Calibration data must be sufficient to improve the accuracy of parameter estimation.

Summarize

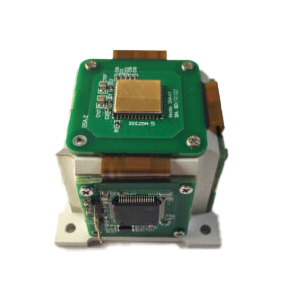

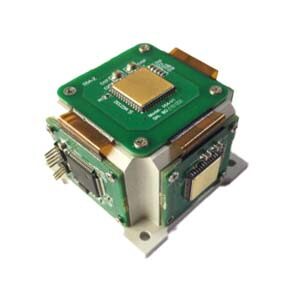

IMU calibration is widely used in many fields, such as drone navigation, robot positioning, augmented reality, etc. With the development of technology, the accuracy and stability of IMUs continue to improve, and its application scope continues to expand. In the future, with the emergence of new IMU sensors and calibration methods, IMU calibration will be more accurate and efficient, providing strong support for the development of related fields. ERICCO's independently developed product MEMS IMU, such as ER-MIMU-01, accurately calibrates the IMU and improves the navigation and positioning accuracy of the system. If you want to learn about or purchase MEMS IMU, please contact us.

More Technical Questions

1.IMU working principle & Tactical grade IMU product recommendations

2.Choosing an IMU: FOG IMUs vs MEMS IMUs

3.Application of IMU in the Field of Drones

5.What is the Difference Between IMU and AHRS?

Products in Article