It is crucial to accurately guide the drill bit underground. Traditional directional drilling relies heavily on magnetic sensors, but what to do when the magnetic field environment is unreliable? Gyroscope while drilling (GWD) technology came into being - it is free from magnetic interference and is the key to achieving high-precision wellbore positioning.

Limitations of traditional solutions

Although mechanical gyroscopes and fiber optic gyroscopes have played an important role, they are often unable to perform in harsh underground environments. Their size, cost and sensitivity to extreme shock and vibration make it difficult for them to meet the needs of modern high-intensity drilling operations.

Breakthrough in MEMS technology: Small and powerful solutions

Advanced MEMS (micro-electromechanical system) gyroscopes have brought about a revolution. Their compact size, excellent ruggedness and excellent cost-effectiveness have completely changed the way downhole measurements are made, making high-precision gyro measurements near the drill bit a reality.

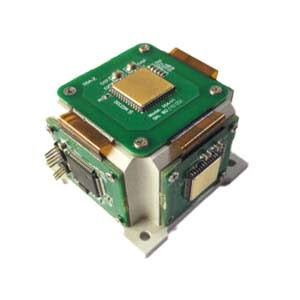

Take the ER-3MG-041 three-axis north-seeking MEMS gyroscope as an example to see how modern GWD works:

Small and flexible, easy to integrate:

Solid-state design, only 27x26x34mm in size and 40g in weight, can be seamlessly integrated into MWD/LWD tools, logging instrument strings or rotary steerable systems (RSS).

It can be deployed as part of the bottom hole assembly (BHA) (working with tools such as mud motors and RSS) without fear of downhole space limitations.

High-precision dynamic perception:

Three high-precision MEMS gyroscopes continuously measure the rotational angular velocity (°/s) of the drill tool in three orthogonal directions.

Built-in accelerometers provide auxiliary data.

The combination of the two solves the key wellbore orientation parameters in real time: well inclination, azimuth (true north direction), and tool face angle.

Independent north-seeking, no fear of magnetic disturbance

Core advantages:

The core advantage of ER-3MG-041 lies in its independent north-seeking capability, which is completely unaffected by the magnetic field. It determines the true north direction by accurately measuring the angular velocity component of the earth's rotation.

Effectively avoid magnetic interference errors caused by casing, formation minerals or adjacent wells, and positioning is more accurate and reliable.

Excellent performance, adaptable to harsh environmental conditions:

Provides optional range (±50~200°/s) and excellent stability indicators (zero bias instability 0.01°~0.02°/hour, angular random walk 0.0025~0.005°/√hour).

Can adapt to various drilling dynamics, significantly reduce angular drift during long-term operations, and ensure strict control of the wellbore trajectory.

Data value: from measurement to precise trajectory

Continuously generated high-precision angular velocity and acceleration data can be processed underground or transmitted to the ground in real time.

Based on these data, combined with reference points, the precise XYZ coordinates of the drill can be calculated.

Finally, an accurate 3D trajectory map of the wellbore is constructed, which is crucial for hitting geological targets and avoiding wellbore collisions.

Rugged and cost-controlled: the core value of MEMS GWD

Compared with traditional gyro technology, ER-3MG-041 fully demonstrates the advantages of MEMS in downhole applications:

Super strong robustness: All-solid-state, single-body inner platform design provides excellent shock and vibration resistance, and is not afraid of harsh drilling environments.

High cost performance: The relatively low cost makes the integration of high-performance multi-axis gyroscopes in MWD/LWD tools an economically feasible solution, supporting OEM customization services.

Application Techniques

1.Main features of MEMS gyroscope

2.Sensitive structure analysis of MEMS gyroscope

3.The analysis of damping in MEMS gyroscope

4.The impact of turntable error on MEMS gyroscope calibration

5.How does MEMS gyroscope work in harsh high temperature environment?

6.Error Generation Mechanism of MEMS Gyroscope Under High Acceleration Condition