In directional drilling and logging—core operations in oil and gas exploration, mineral development, and geological engineering—precise attitude control, wellbore trajectory monitoring, and reliable data acquisition remain significant challenges in traversing complex formations. Faced with the demanding requirements of confined spaces, extreme environments, and long-distance operations, traditional measurement methods often fall short.

The Core of Precise Positioning

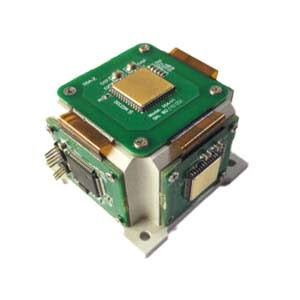

As a key technology in directional drilling, gyroscopic drilling relies on high-precision inertial sensors (gyroscopes and accelerometers) to calculate well inclination, azimuth, and tool face angle in real time. Today, MEMS gyroscopes, such as the ER-3MG-091, with their miniaturized design and groundbreaking performance, are becoming the cornerstone of precise downhole sensing capabilities, providing essential navigation data for complex drilling operations.

Breakthrough Accuracy: Navigation-Grade Performance, Downhole Perception

The core value of the ER-3MG-091 lies in its navigation-grade MEMS gyro accuracy, which can keenly detect minute angular velocity changes.

Excellent Stability: It offers a bias instability of 0.01°/hr or 0.02°/hr (optional), effectively suppressing error accumulation during long-duration operations. It is particularly suitable for precise corrections in ultra-long horizontal wells or complex trajectories.

Extremely Low Noise: Angular random walk is as low as <0.0025°/√h, ensuring minimal measurement error over long periods of time, laying the foundation for accurate attitude estimation and heading maintenance.

Wide Adaptability: Multiple measurement ranges of 50°/s, 100°/s, and 200°/s are available, seamlessly covering diverse operating conditions from conventional drilling to high-speed rotary drilling.

Miniature Design: Unafraid of Space Constraints

The ER-3MG-091 has been miniaturized to address the stringent space constraints of downhole tools (such as MWD measurement while drilling, LWD logging while drilling systems, and gyro inclinometers):

Compact Cylindrical Configuration: Measuring only 120mm x 30mm in diameter and weighing ≤150g, this miniature cylindrical design overcomes space constraints and is easily integrated into a variety of narrow downhole instruments.

Small Diameter Advantage: Significantly reduces dependence on borehole diameter, making it an ideal choice for small-diameter directional drilling applications.

Conquering Extremes: Reliable Operation in Extreme Environments

The harsh drilling environment (high temperature, high pressure, and strong vibration) places a heavy strain on sensors. The ER-3MG-091 demonstrates exceptional durability:

Wide Temperature Range: The standard model operates from -45°C to +85°C. For even more demanding logging environments, the ER-3MG-091H high-temperature model offers stable operation in extreme temperatures from -40°C to +125°C. High-Speed Real-Time Communication: Utilizing an RS-422 interface with a default baud rate of up to 460,800 bps and a data refresh rate of 400 Hz, this ensures high-speed, real-time, and lossless transmission of measurement data, enabling rapid decision-making.

Summary

The ER-3MG-091 3 axis MEMS gyroscope, with its navigation-grade accuracy, miniaturized structure, and excellent environmental adaptability, addresses the challenges of high-precision measurement in complex drilling environments. It not only improves directional drilling trajectory control accuracy and logging data reliability, but also broadens its application in complex scenarios such as small-diameter drilling. It is a key driver of downhole measurement technology advancements.

Application Techniques

1.Main features of MEMS gyroscope

2.Sensitive structure analysis of MEMS gyroscope

3.The analysis of damping in MEMS gyroscope

4.The impact of turntable error on MEMS gyroscope calibration

5.How does MEMS gyroscope work in harsh high temperature environment?

6.Error Generation Mechanism of MEMS Gyroscope Under High Acceleration Condition