Digital Output Type 2 Axis Tilt Sensor

Introduction

ER-TS-3262DI is a serial dual-axis inclinometer with MEMS technology and digital output designed for the field of industrial control, built-in high-precision 16bit A/D differential converter, through N filtering algorithm, which can measure the angle of sensor output relative to the horizon taltilt and pitch tilt. The output interface has RS485, RS232, RS422, TTL, CAN, MODBUS to choose from.

The product is equipped with a high-precision digital sensor, which can correct the temperature drift of the sensor according to the monitoring temperature change of the built-in temperature sensor to ensure the repeatability of the product in low and high temperature environments. The output corresponding frequency is 100Hz, which is a real industrial product, with reliable and stable performance, good scalability, and a variety of output options, making it suitable for various industrial control environments.

Features

Dual axis tilt monitoring

Full range accuracy 0.02°, resolution 0.005°

Output frequency 5~100HZ (optional)

Wide voltage input DC 9~36V

Wide temperature working -40~+85℃

Measuring range: 0~±90° (optional)

High vibration resistance >20000g

Baud rate 2400~115200 (adjustable)

IP67 protection

Can output RS232/RS485/TTL/MODBUS (optional)

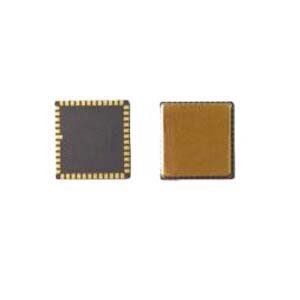

Small volume (46*35*8mm) customizable

Applications

High voltage wire tower pole monitoring

Satellite solar antenna positioning

AGV trolley

Mining machinery, oil logging equipment

Medical equipment

Tilting leveling

Hydraulic lifting platform

Inclination monitoring

Angle control of various construction machinery

Inspection of bridges and dams

Specifications

| Parameter | Condition | ER-TS-3262DI-10 | ER-TS-3262DI -30 | ER-TS-3262DI-60 | ER-TS-3262DI-90 | Unit |

| Measuring range | / | ±10 | ±30 | ±60 | ±90 | ° |

| Measurement axis | / | X,Y axis | X,Y axis | X,Y axis | X,Y axis | / |

| Zero temperature drift | -40~85° | ±0.008 | ±0.008 | ±0.008 | ±0.008 | °/℃ |

| Sensitivity temperature coefficient | -40~85° | ≤100 | ≤100 | ≤100 | ≤100 | ppm/℃ |

| Frequency response | DC response | 100 | 100 | 100 | 100 | Hz |

| Resolution | / | 0.005 | 0.005 | 0.005 | 0.005 | ° |

| Accuracy | -40~85℃ | 0.02 | 0.03 | 0.04 | 0.05 | ° |

| Long-term stability | -40~85℃ | <0.023 | <0.035 | <0.045 | <0.054 | ° |

| Power on start time | / | 0.2 | 0.2 | 0.2 | 0.2 | s |

| Response time | / | 0.01 | 0.01 | 0.01 | 0.01 | s |

| Rate | 5Hz output, 15Hz, 35Hz, 50Hz can set (RS485without this function) | |||||

| Output signal | RS232/RS485/RS422/TTL/PWM/CAN/MODBUS | |||||

| Average working time | ≥45000 hours/time | |||||

| Impact resistant | 20000g, 0.5ms, 3 times/axis | |||||

| Shock resistant | 10grms, 10~1000Hz | |||||

| Insulation resistance | ≥100MΩ | |||||

| Waterproof level | IP67 | |||||

| Cable | Standard 1.5 m length, wear resistance, oil proof, wide temperature, shielding cable 4*0.3mm² | |||||

| Weight | 10g (excluding boxes) | |||||

Application Techniques

1.The Difference between Tilt Sensor and Gyro Sensor

3.How to install the tilt sensor?

4.What are Tilt Switches and Tilt Sensors?

5.How to Use the Tilt Sensor and How to Install It?

6.Do you Know the Working Principle of Inclinometer ?

More Products